- Home

- Customization Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-07 Origin: Site

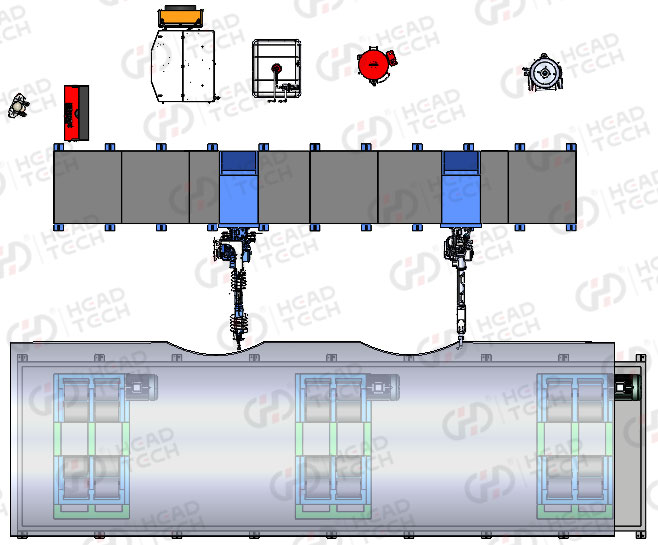

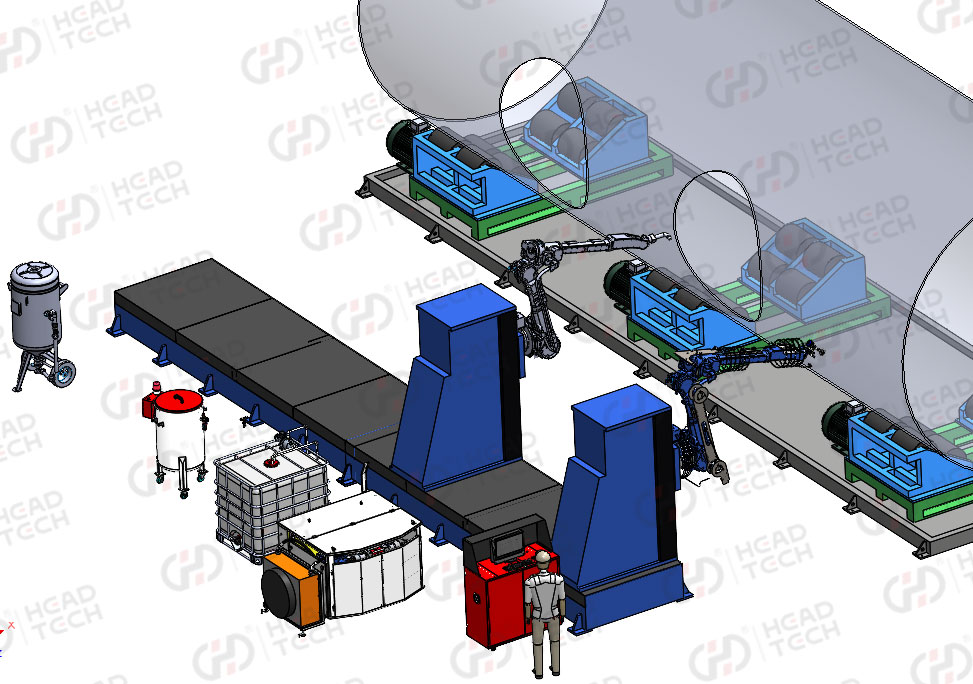

Shanghai Pelz Mechanical Equipment Co., Ltd., a professional pressure vessel manufacturer, faced challenges in pipe cutting and flange prefabrication—including thermal deformation, dimensional inaccuracies, and poor welding fit. HEAD provided a fully integrated solution consisting of a robotic arm, waterjet cutting system, high-pressure pump, abrasive delivery unit, and a circulating water filtration tank.

By combining cold-state waterjet cutting with multi-axis robotic arm path programming, the system enables precise angled cuts with excellent edge quality. Powered by AC 380 V / 50 Hz with total power around 43 kW, the system delivers cutting pressures up to 380 MPa. Strict standards are applied to pneumatic and water input. The cutting work area measures 2.5m × 2.7m × 2.5m.

The project took about six months from initiation to delivery. After implementation, cutting and grinding efficiency improved by 2–3 times, weld joint quality improved significantly, and both labor costs and post-processing time were greatly reduced. The client praised the system’s ease of use and cutting consistency. The solution directly addressed three core pain points: productivity, precision, and environmental safety.

Company Name: Shanghai Pelz Mechanical Equipment Co., Ltd.

Industry & Position: A specialized manufacturer of pressure vessels and high-end mixing equipment, widely serving chemical, petrochemical, and power industries, with strict requirements for welding precision and structural integrity.

Why Waterjet + Robotic Arm?

Cold cutting, zero heat-affected zone: Prevents thermal damage and residual stress, improving weld reliability at flange joints.

Angled cutting capability: Enables complex nozzle geometries with better weld fit.

Client Performance Requirements:

Cutting accuracy within ±0.1 mm

Enhanced productivity and quick adaptability to varying pipe diameters

Environmentally friendly & safe: no flames, no fumes, closed-loop waterjet operation, compliant with modern workshop standards

Robotic arm & control cabinet: For path programming and precise execution of cutting and grinding tasks

High-pressure pump system: Provides up to 380 MPa UHP waterjet power for processing various pressure vessel materials

Abrasive delivery unit: Supplies garnet on demand to maintain cutting quality

Water filtration tank: Supplies softened water and supports recycling to reduce water consumption

| Parameter | Value |

|---|---|

| Power Supply | AC 380 V, 50 Hz |

| Total Power | Approx. 43 kW |

| Operating Temperature | 5–30 ℃ |

| Air Supply | 0.6–0.8 MPa, ≥300 L/min |

| Water Supply | Softened water, ≥ 0.4 MPa |

| Cutting Work Area | 2.5 m × 2.7 m × 2.5 m |

Adjustable roller supports & track spacing: Allows fast manual setup for various pipe diameters

Multi-station coordination: Supports simultaneous waterjet cutting, external grinding, and internal grinding via integrated robotic arms

Teach pendant + path programming: Manual marking first, followed by robotic teaching and programming to ensure high accuracy and collision avoidance

HEAD waterjet systems offer major advantages in cold cutting, high efficiency, and complex trajectory control. They support 1–200 mm thick materials and any custom shape.

Project Timeline:

From requirements analysis to final commissioning: approx. 6 months

Key Technical Milestones:

Robotic path planning & anti-collision validation

Roller stand adjustment for multi-diameter compatibility

Full system synchronization and stability tuning

On-Site Workflow:

Manual adjustment of roller support and track spacing

Marking of cutting paths using templates and guides

Robotic teaching and programming

Trial run for collision check, followed by formal production: waterjet cutting → outer grinding → inner grinding

2–3x higher efficiency compared to traditional gas cutting and manual grinding

Smooth, accurate cut surfaces, minimal need for rework

High automation level reduces labor reliance and labor cost

Supports multi-spec production for expanding business opportunities

“The system is easy to operate, safe, and environmentally friendly. Cutting accuracy is excellent, and weld structures are more reliable.”

The client highly praised the system’s stability and eco-friendly performance.

By adopting HEAD’s integrated robotic arm + waterjet + abrasive + water recycling system, Shanghai Pelz successfully addressed long-standing issues in pressure vessel fabrication—such as heat-induced distortion, low accuracy, and high environmental demands.

The project was completed in six months, and since going live, the system has run smoothly, greatly improving productivity and assembly quality—ultimately boosting the client’s ability to scale and secure new business.

content is empty!