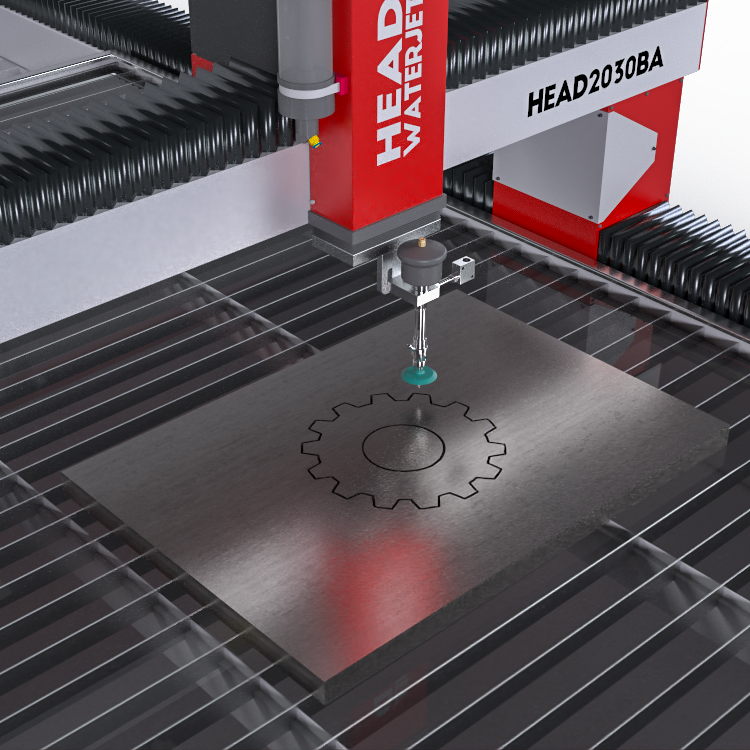

Top 5 Best Quality Waterjet Machine Brands

Top 5 Best Quality Waterjet Machine BrandsChoosing the right waterjet machine is a critical investment in your manufacturing future. The quality of your machine directly impacts precision, operational uptime, running costs, and ultimately, your profitability. With numerous brands on the market, iden

English

English