- Home

- Customization Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

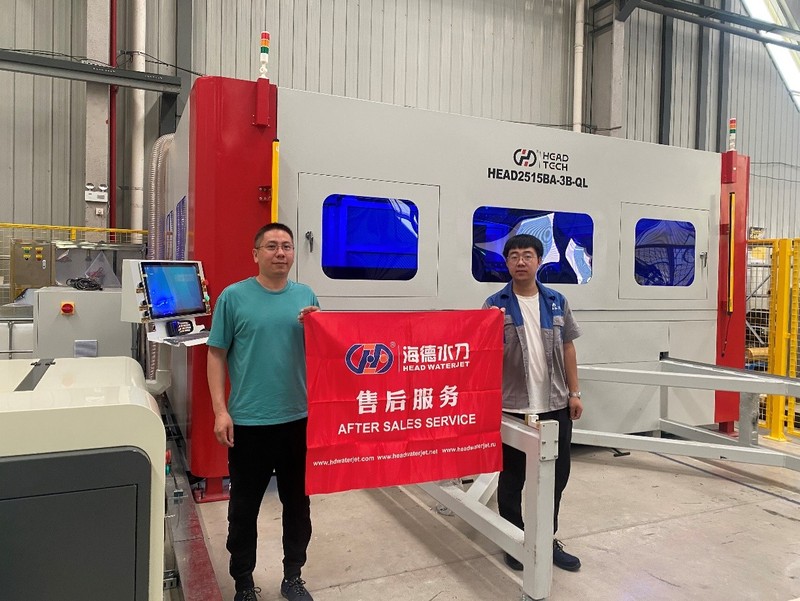

HEAD2515BA-3B-QL

HEAD

hs code:84565000

| Availability: | |

|---|---|

Product Description

Our client is the Chinese subsidiary of one of Europe’s largest polyurethane foam manufacturers. As a long-term supplier to luxury automotive brands, they specialize in producing car seats, acoustic insulation, and interior parts. Facing increased demand and diverse design specifications, they urgently needed a solution that could boost productivity, deliver precise cuts, and maintain a clean working environment.

High-Volume Processing Needs

Complex Shape & Precision Cutting Requirements

Dust & Contamination from Traditional Blades

Water Mist Control in the Workshop

Labor-Intensive Operations Requiring Automation

HEAD Technology developed the HEAD2515BA-3B-QL, a high-performance pure water cutting machine paired with the HEAD-3D-20AS cutting head. Purpose-built for flexible materials like sponge and foam, the system enables clean, precise, and high-speed cutting without abrasives.

Fully Enclosed Structure: Mist separation system ensures no leakage of water vapor

Auto Loading/Unloading Platform: Enhances workflow efficiency and reduces manual handling

Follow-Type Water Collection System: Prevents water splash for a clean environment

Cutting Speed Up to 35m/min: Ideal for mass production with high throughput

Safety Light Curtain System: Guarantees operator and machine safety

Water Recycling System: Filters and reuses wastewater, supporting eco-friendly production

✅ Reduced Labor Costs – Automates the cutting process, minimizing human involvement

✅ 30% Boost in Production Efficiency – Speeds up delivery cycles

✅ Consistent Cutting Quality – Smooth edges and precise shapes

✅ Improved Customization Capabilities – Handles complex and varied product demands

✅ Cleaner, Greener Workshop – Aligned with modern manufacturing standards

“HEAD’s system is a game-changer for our foam processing. It’s clean, fast, safe, and reliable. We’re now able to deliver more orders with better quality — and faster than ever.”

HEAD Waterjet’s pure water cutting solution has empowered this global leader to upgrade their foam processing workflow, while reducing costs and improving sustainability. We continue to deliver cutting-edge, flexible material cutting solutions tailored to the evolving needs of advanced manufacturers.

Our Service

Rapid Global Response

⏱ Downtime disrupts production; we support with 24/7 online technical help and fast dispatch of service engineers to minimize downtime

Professional Installation & Training

We offer complete installation, commissioning, hands‑on operator training, and remote guidance to optimize efficiency from day one

Preventive Maintenance & Upgrades

Our maintenance contracts include scheduled servicing, spare‑parts reminders, and software/CNC updates to keep your machine precise and reliable

Genuine Spare Parts Supply

✔ Only authorized parts ensure performance, safety, and longevity—no unknown quality risks Globally Certified Technicians

Engineers in every region undergo HEAD’s training and assessment. Since 2024, distributor engineers worldwide receive factory‑based certification to deliver consistent expert support

Avoid costly delays: Fast response and expert fixes reduce production loss.

Empower your team: Learn to operate and maintain effectively from day one.

Ensure long-term reliability: Proactive maintenance prevents breakdowns.

Secure quality and safety: Only genuine parts maintain integrity.

Consistent experience worldwide: Certified support no matter where you are.