- Home

- Customization Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-29 Origin: Site

The stone industry is evolving fast. Architects and homeowners alike expect seamless granite countertops, flawless marble inlays, and complex mosaic patterns—delivered on schedule and on budget. For fabricators, however, conventional methods such as bridge saws and routers often mean high scrap rates, heavy polishing work, and limited design flexibility. This article explains how HEAD Waterjet helps stone shops cut costs, expand capabilities, and win premium projects.

Breakage & chips: Curves, tight radii, and thin sections are prone to cracks using mechanical tools.

High waste on expensive slabs: Natural variation and wide kerfs push scrap toward 15–20% in decorative work.

Labor-intensive finishing: Rough edges require polishing and rework, inflating cycle time and cost.

Limited design freedom: Logos, medallions, and precise mosaics demand complex setups or outsourcing.

Slow turnaround: Complex jobs tie up machines and skilled operators, capping revenue.

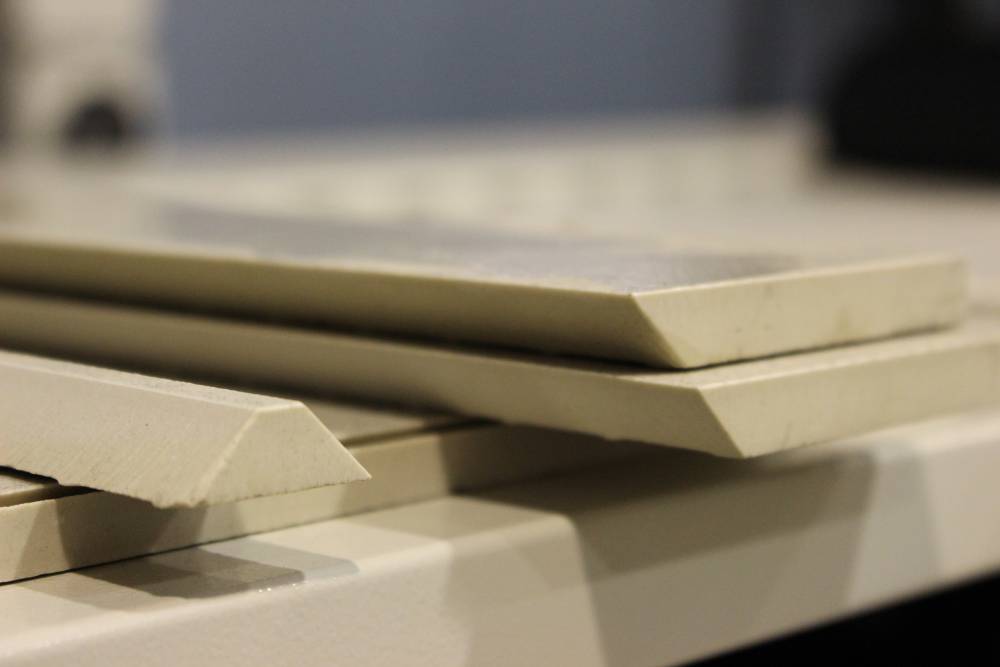

HEAD Waterjet cuts with a high-pressure water stream (with abrasive as needed), creating a cold cut: no burns, no micro-cracks, and minimal edge damage. Systems are engineered for marble, granite, quartz, engineered stone, and ceramics.

Crack-free, smooth edges: Typical accuracy of ±0.1 mm reduces polishing and rework.

Material savings: Thin kerf + optimized nesting can cut waste by up to 20%.

Complex patterns from CAD/CAM: Curves, logos, medallions, and mosaics with repeatable precision.

Imaging & mapping: Integrates with slab scanners to align veins, avoid defects, and maximize yield.

Multi-material capability: One platform handles stone, ceramics, glass, and even composites/metal for mixed projects.

A Middle East fabricator cutting luxury marble countertops struggled with 15–20% scrap and lost bids on hotel lobbies needing intricate inlays. After installing a HEAD 5-axis waterjet and adopting slab imaging:

Yield rose by ~15%: Vein-aware nesting avoided defects and maximized usable area.

Rework dropped by ~70%: Clean edges cut polishing time to a fraction.

Premium contracts secured: Medallions and complex mosaics won high-margin hospitality projects.

Profitability improved by ~20%: Lower labor + reduced scrap + premium pricing.

Use low-pressure pierce → ramp-up sequences; place lead-ins off-feature so witness marks fall in waste. For holes, helical entry helps protect fragile edges.

Match nozzle ID and abrasive mesh (80#–120# typical) to thickness and finish. Run quick DOE trials to balance edge quality, cut speed, and media cost.

Leverage CAD/CAM with slab photos to align patterns across pieces. Common-line cutting and minimized traverses reduce cycle time and abrasive use.

Stable slats and damped tanks support heavy slabs while letting spent abrasive settle away from the cut—improving finish quality and dimensional stability.

Countertops & vanities: Sink cutouts, faucet holes, and cooktop slots with chip-free edges.

Mosaics & medallions: Curves, tight radii, and inlays in marble/granite/quartz.

Floor & wall features: Logos, geometric panels, and decorative reveals.

Architectural stone: Precisely matched patterns for lobbies and façades.

Lower cost per project: Less scrap, less polishing, fewer operator hours.

Faster delivery: Automated programs and predictable cycles compress lead times.

Higher win rate: Waterjet capability differentiates bids for premium work.

Future-proof platform: One machine serves stone, ceramics, glass, and composites.

20+ years of expertise: Stone-focused motion control and application know-how.

Global trust: Installations in 80+ countries with training and lifetime support.

Configurable systems: From compact tables to advanced 5-axis/robotic cells.

Customer loyalty: Many fabricators add more HEAD machines as their business scales.

Cut waste up to ~20% and reduce polishing with cold, precise waterjet edges.

Deliver complex inlays and mosaics straight from CAD/CAM with repeatable accuracy.

Align veins and avoid defects with imaging to maximize slab yield and aesthetics.

Use one platform to serve stone, ceramics, glass—and grow into high-value markets.

Ready to reduce waste and win premium stone projects? Share your drawings, target tolerances, and preferred finishes—HEAD engineers will run sample cuts and propose a configuration tailored to your mix.

Website: www.headwaterjet.net

Email: sale2@hdwaterjet.com

WhatsApp: +86 15942048409

HEAD Waterjet – Cutting Beyond Limits, Creating More Value for Stone Fabricators.