- Home

- Customization Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-28 Origin: Site

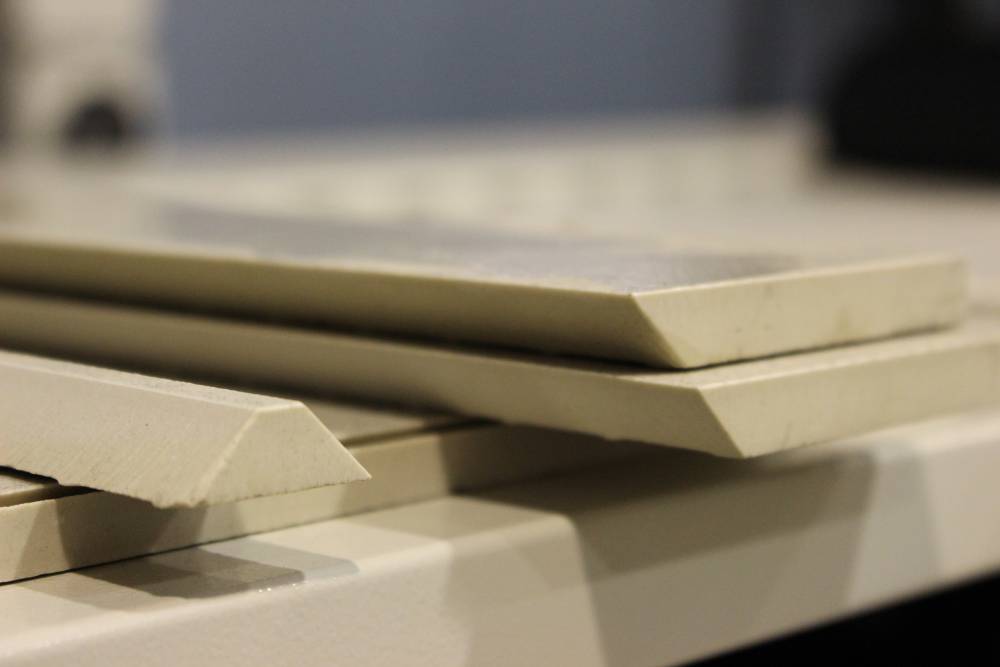

Quartz countertops continue to outpace natural stones in residential and commercial projects because they deliver a rare mix of durability, stain resistance, and design consistency. Yet behind every polished surface lies a demanding fabrication process: large slabs must be measured, nested, cut, and finished to tight tolerances. Among all operations, hole-cutting for sinks, faucets, and cooktops is a persistent bottleneck. It drives rework, consumes tooling, and can jeopardize delivery schedules if not executed precisely.

This article details how a fast-growing quartz countertop manufacturer in Asia replaced conventional drilling/routing with a HEAD waterjet cutting system specifically configured for high-throughput hole-cutting. By transitioning to cold, abrasive waterjet, the factory realized cleaner edges, lower scrap, and a step-change in throughput—while improving worker safety and expanding design flexibility for custom jobs.

The global quartz surface market has expanded rapidly on the back of urbanization, remodeling cycles, and the hospitality sector’s demand for durable, hygienic materials. With procurement teams benchmarking suppliers across regions, fabricators that pair consistent quality with predictable lead times capture the lion’s share of repeat contracts. In this environment, process reliability and OEE (Overall Equipment Effectiveness) in cutting cells matter as much as raw material pricing.

Before the upgrade, the manufacturer relied on diamond core drills, routers, and partial CNC operations. Over time, four chronic issues emerged:

Excessive Tool Wear: Quartz’s hardness accelerated diamond bit consumption, causing frequent changeovers and rising consumable spend.

Edge Defects and Micro-Cracks: Mechanical cutting introduced chips and stress fractures around cutouts, requiring secondary polishing or—worse—scrap.

Slow, Operator-Dependent Cycles: Manual setup and monitoring constrained throughput and made output quality dependent on operator skill.

Dust, Vibration, and Safety Risks: Dry cutting generated dust exposure and equipment vibration that heightened HSE concerns.

After on-site trials and a cost/benefit analysis, the team selected a HEAD 4020 waterjet platform with configuration options optimized for stone fabrication. The decision rested on five pillars:

Waterjet removes material via high-pressure water and abrasive, avoiding heat input. The result is no thermal micro-cracking, discoloration, or structural weakening—a core requirement for stone integrity and long-term performance at the installation site.

Kerf geometry and controllable feed rates produce clean, chip-free edges. For most sink and faucet cutouts, only a light pass (if any) is needed before assembly, cutting hours of manual polishing each week.

Programs are generated directly from kitchen drawings. Operators switch between round, oval, square, and bespoke shapes without swapping physical tools. This flexibility enables profitable, small-batch customization with enterprise-grade repeatability.

Instead of high-capex tool inventories and unpredictable diamond wear, the system uses standardized abrasive and water. This creates a stable cost per cut model that finance teams can forecast with confidence.

Automatic height control, programmable piercing strategies, and guarded enclosures reduce operator intervention and improve safety and ergonomics. Closed-loop water handling simplifies shop compliance efforts.

Deployment began with a pilot line focused on the highest-volume SKUs. A cross-functional team mapped legacy cycle times, tool change intervals, defect Pareto, and rework hours. Within the first month:

Programs: Standard sink cutouts and faucet holes were parameterized as reusable templates with adjustable dimensions.

Nesting: HeadCAM nesting condensed cut patterns to minimize traverse and abrasive consumption.

Quality Gates: On-table inspection fixtures validated hole diameter, ovality, and edge quality at the cell before slabs moved to finishing.

~40% Faster Hole-Cutting Cycles: Typical sink cutouts dropped from 6–8 minutes to under 4 minutes per piece, improving daily output and on-time delivery.

~$10,000/Month Tooling Savings: Eliminating diamond drill/router replacement and reducing maintenance generated immediate cash impact.

Defects Down, Yields Up: Chip-free edges sharply reduced rework, freeing polishing capacity for value-added finishing.

Scheduling Stability: Fewer unplanned stoppages and predictable consumables improved production planning and inventory turns.

Safer, Cleaner Cell: Lower vibration and enclosed cutting reduced dust exposure and improved operator satisfaction.

Staged or dynamic piercing programs prevent spall in dense quartz surfaces. Where applicable, pre-drilled pilot holes are replaced by low-pressure pierce + ramp-up sequences to protect the surface finish.

Consistent mesh size and controlled feed maintain edge quality while avoiding abrasive overuse. Facilities often settle on a narrow granulometry window after short DOE trials to balance cut speed, edge finish, and media cost.

Offset arcs and micro-tabs are programmed to ensure start/stop points remain off-feature, eliminating witness marks on visible edges.

Stable slab support and anti-vibration strategies are critical. HEAD tables incorporate water tank damping and slat configurations that support heavy quartz while allowing spent abrasive to settle away from the cut zone.

Modern CAD/CAM optimizes head travel and integrates common-line cutting where appropriate, shaving seconds from each cycle—cumulatively saving hours per shift.

Diamond Drilling/Routing: Lower capex but high consumable burn, more chipping, operator intensive, and dust exposure.

CNC with Mechanical Tools: Good for straight profiling; still subject to wear, thermal friction, and toolpath limitations on delicate edges.

Laser/Plasma: Not suited to quartz due to heat-affected zones, discoloration risk, and micro-cracking.

HEAD Waterjet: Cold, clean, programmable, multi-shape, with predictable cost per cut and superior edge finish.

Once the team stabilized sink and faucet programs, engineers extended waterjet use to:

Cooktop slots with rounded internal corners to reduce stress concentration.

Logo inlays and decorative reveals for premium projects.

Mixed-material assemblies, such as quartz + steel brackets or glass inserts, leveraging waterjet’s multi-material capability.

Consistent geometry and chip-free edges simplify downstream sealing and hardware fitment, reducing service callbacks. With traceable programs and logged parameters, fabricators can demonstrate process control to commercial clients and auditors.

Finance teams appreciated the transition from volatile diamond tool spend to a steady cost-per-meter (CPM) based on abrasive, water, and energy. Stable CPM simplifies pricing, quotation, and contract negotiations for large roll-outs.

HEAD Waterjet’s portfolio spans stone, glass, metal, and composites, but its stone-oriented engineering is what sets it apart for countertop shops:

Stone-tuned motion control for steady feed on brittle surfaces.

Rugged tanks and slat systems sized for full-format quartz slabs.

CAD/CAM toolchains with libraries for common sink/faucet standards.

Global service—installation, training, and lifetime technical support in 80+ countries.

Map the Baseline: Record cycle time, defect rates, tool costs, and rework hours for the current hole-cutting process.

Pilot SKUs: Start with top-volume sinks/faucets; build template programs with parameterized dimensions.

DOE on Abrasive & Feeds: Run quick experiments to lock in media mesh, pressure, and speed for your most common quartz colors/densities.

Install Quality Gates: Add on-cell checks for diameter/ovality and edge finish before slabs leave the cutting table.

Train & Document: Certify operators, standardize maintenance, and document changeover routines.

“Switching to waterjet didn’t just make individual cuts faster—it made our schedule reliable. We quote confidently now, because the process is stable.”

Efficiency: Expect ~40% cycle-time reduction for common cutouts once programs and nesting are tuned.

Quality: Cold cutting yields chip-free edges that minimize polishing and eliminate micro-cracks.

Cost: Tooling savings and predictable CPM improve margins and quoting accuracy.

Flexibility: CAD/CAM workflows unlock profitable custom work without physical tool changeovers.

Safety: Enclosed, low-vibration cells support cleaner, safer operations and regulatory compliance.

Whether you operate a single fabrication shop or a multi-site network, upgrading to a HEAD waterjet hole-cutting cell can standardize quality, compress lead times, and stabilize costs. The same platform extends naturally to decorative inlays, cooktop slots, and mixed-material work—future-proofing your investment as client demands evolve.

Discuss your current cycle times, target throughput, and quality requirements with our engineering team. We’ll help you scope a cell configuration, run sample cuts, and model ROI with your SKUs.

Website: www.headwaterjet.net

Email: sale2@hdwaterjet.com

WhatsApp: +86 15942048409

HEAD Waterjet – Cutting Beyond Limits, Creating More Value for Your Business.

content is empty!