- Home

- Customization Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-13 Origin: Site

In industrial manufacturing and maintenance, creating openings in metal tanks is a critical operation found in sectors like oil & gas, chemical storage, water treatment, and food processing. The process demands precision, safety, and structural integrity—areas where traditional heat-based cutting methods often fall short. In contrast, industrial water jet cutting machines offer a superior, cold-cutting alternative. This article discusses the key advantages and real-world practices of using industrial waterjet cutting in metal tank processing, featuring insights from HEAD Waterjet, an industry-leading manufacturer.

Key advantages that make waterjet cutting technologies especially effective in tank opening scenarios include:

Precision & No Thermal Distortion: A cold-cut process ensures no heat-affected zones, preserving material properties and avoiding warping

Material Versatility: Capable of cutting a broad range of metals—including stainless steel, aluminum, titanium, and copper—as well as composites, all with high accuracy

Safety in Hazardous Environments: Cold, spark-free operations are safe in flammable zones like petrochemical plants

Environmental Benefits: Does not produce toxic fumes or hazardous byproducts; water-cooling further protects materials

Portable waterjet cutting machines allow precise and safe openings (e.g., manholes, inspection ports) to be made directly on-site, avoiding disassembly.

Waterjet ensures clean, burr-free cuts that streamline assembly, welding, and sealing.

Rapid cutting via portable systems enables safe emergency access without introducing fire or spark risks.

Recent research illustrates how optimizing hydraulic power (via flow rate, not just pressure) substantially enhances cutting performance and cost efficiency . Studies also highlight the evolving applications of abrasive waterjet cutting in manufacturing, with focus on precision and process optimization

As a trusted provider, HEAD Waterjet supplies:

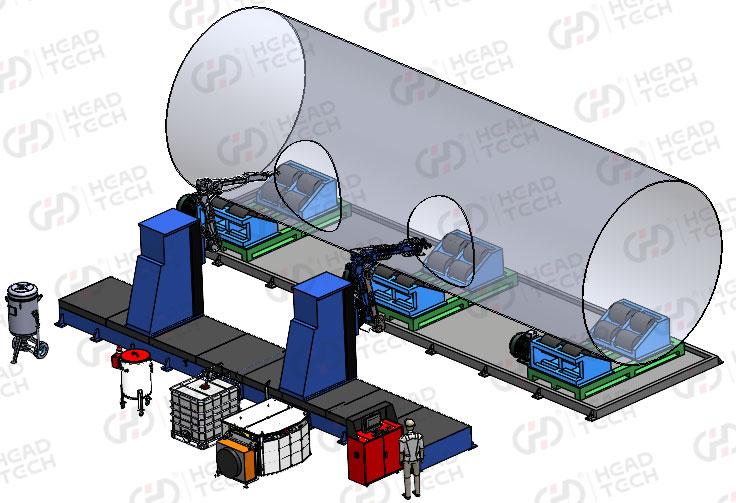

Gantry-Style Industrial Waterjet Systems suitable for large-scale tank panel cutting.

Portable Cutting Units ideal for in-situ modifications and maintenance.

Five-Axis Systems for bevels and complex tank openings.

Features include high-pressure pumps, CNC integration, and smart abrasive handling to balance precision, speed, and operating costs.

Assess Material Specs: Identify thickness, coatings, and metal type for tailored settings.

Optimize Hydraulic Power: Balance flow rate and pressure to maximize cutting efficiency .

Ensure Water Quality: Clean, filtered water helps maintain nozzle lifespan and cutting consistency .

Select the Right Abrasives: Garnet works best for steel; quality affects both cut and cost.

Use Laser Alignment: Ensures precision and reduces rework.

Inspect Cuts Post-Process: Verify dimensional accuracy and surface integrity.

Industrial waterjet cutting stands out as a safe, versatile, and precise method for metal tank opening operations. It overcomes the limitations of heat-based techniques, supports diverse materials, and boosts safety in sensitive environments. Leading the charge, HEAD Waterjet continues to deliver high-performance, cost-effective water jet cutting machines tailored to meet the evolving demands of industrial tank processing.

For safer, cleaner, and more precise metal tank opening solutions, Shenyang HEAD Technology Co., Ltd. offers advanced waterjet cutting machines and expert support.

Email: sale2@hdwaterjet.com

Our technical team is ready to help you select and deploy the ideal water jet cutter for your application, ensuring compliance with both safety and industry standards.

STM Waterjet – Waterjet Cutting Metal: Efficiency, precision, and environmental advantages of metal waterjet cutting

STM Waterjet – Waterjet Cutting: Material diversity, no microstructure hardening, minimal environmental impact

Techni Waterjet – Applications in Oil & Gas: Use cases, material types, and benefits in hazardous sectors

Efficiency of Abrasive Waterjet: Role of hydraulic power optimization in industrial cutting

MDPI Review – Abrasive Waterjet Cutting Trends: Advancements, parameters, and precision in metal fabrication

```