- Home

- Customization Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-16 Origin: Site

Profit Black Hole or Growth Engine?

3 Critical Cost-Control Points That Decide Success or Failure in Stone Processing

For any stone processing business, profit margins are under more pressure than ever. Expensive slabs, fierce competition, and rising labor costs demand that every step of production be closely examined. Yet many factory owners focus only on increasing order volume, while ignoring the hidden “black holes” in their workshop silently consuming their profits.

As equipment experts deeply involved in the waterjet cutting industry, we’ve worked closely with hundreds of stone processors worldwide. What we’ve learned is clear: A factory’s profitability depends less on how many orders it secures—and more on how well it controls these three key costs.

This is the most painful and direct loss. A single slab—worth thousands or even tens of thousands of dollars—can crack or become scrap due to improper handling or cutting errors. That’s a day’s profit gone instantly.

Hidden Killer #1: Handling Damage

Large-format, thin slabs are extremely fragile. Using forklifts or manual handling methods means every move carries a risk. We’ve seen too many cases where a slight collision leads to total slab loss. This is not just wasted material—it disrupts production schedules and damages customer trust.

HEAD’s Solution:

Our patented vacuum suction loading system eliminates the human error risk. With steady, evenly distributed suction, slabs are moved safely from point A to point B. It transforms material handling from a gamble into a guarantee.

Hidden Killer #2: Pattern-Matching Errors and Layout Waste

For high-end stones with natural patterns, poor layout planning causes serious material loss. Achieving seamless pattern continuation (“bookmatching” or “vein-matching”) often sacrifices usable material. Worse, if mismatches are discovered post-cutting, customers may reject the final product entirely.

HEAD’s Solution:

Our photo nesting system brings visibility and precision to layout planning. A high-resolution photo of the slab allows operators to digitally position cut parts directly on the slab image, adjusting angles and positions for optimal pattern alignment and material utilization. The customer can even preview the final look before cutting—a powerful sales and risk-reduction tool.

From loading to positioning, cutting, washing, and unloading, each slab passes through multiple stages. Every delay in this process increases your labor, energy, and time costs.

The root problem? Fragmented workflows. Operators spend time recalibrating and switching between machines, which not only slows production but increases the risk of human error.

HEAD’s Solution:

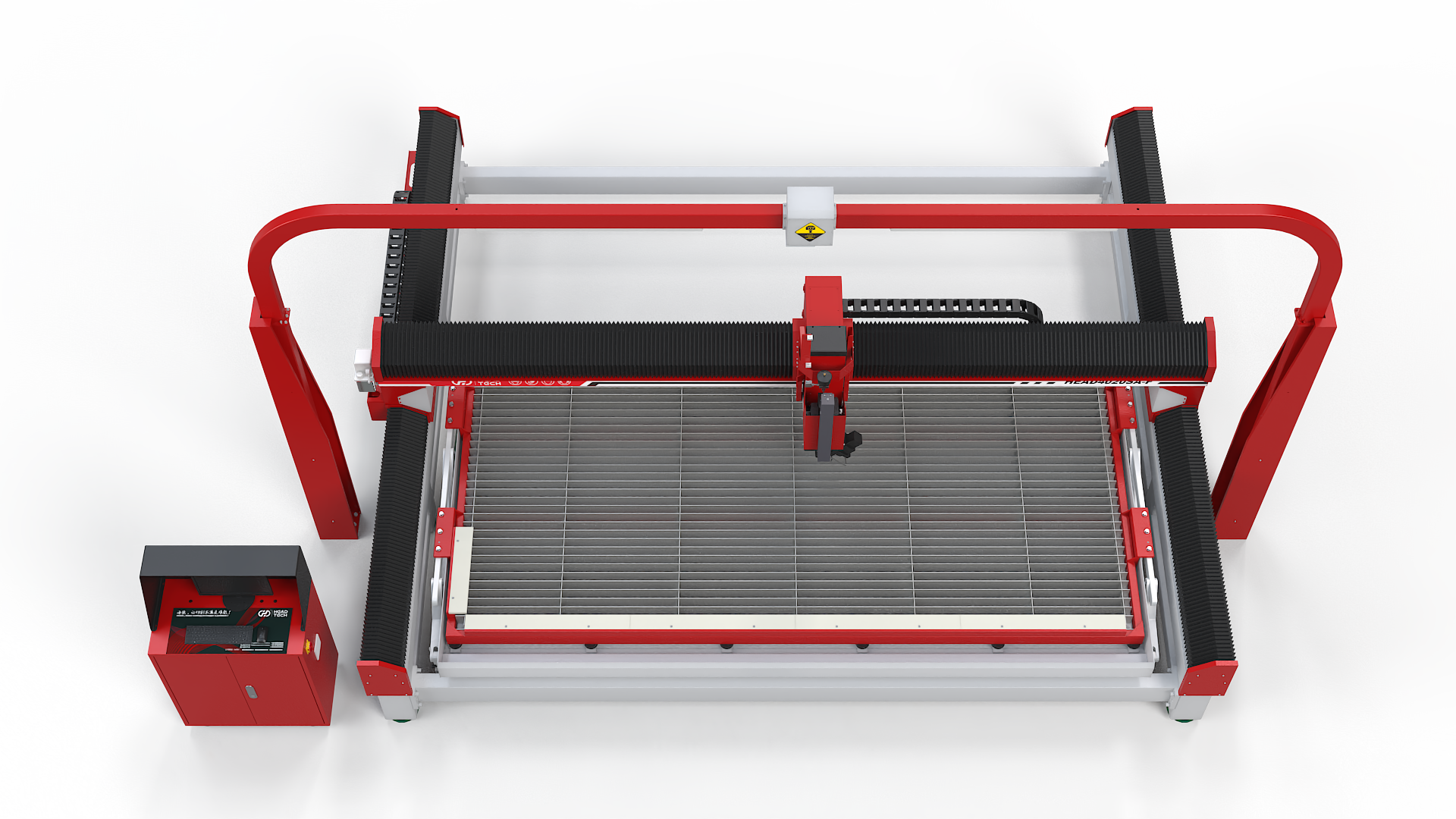

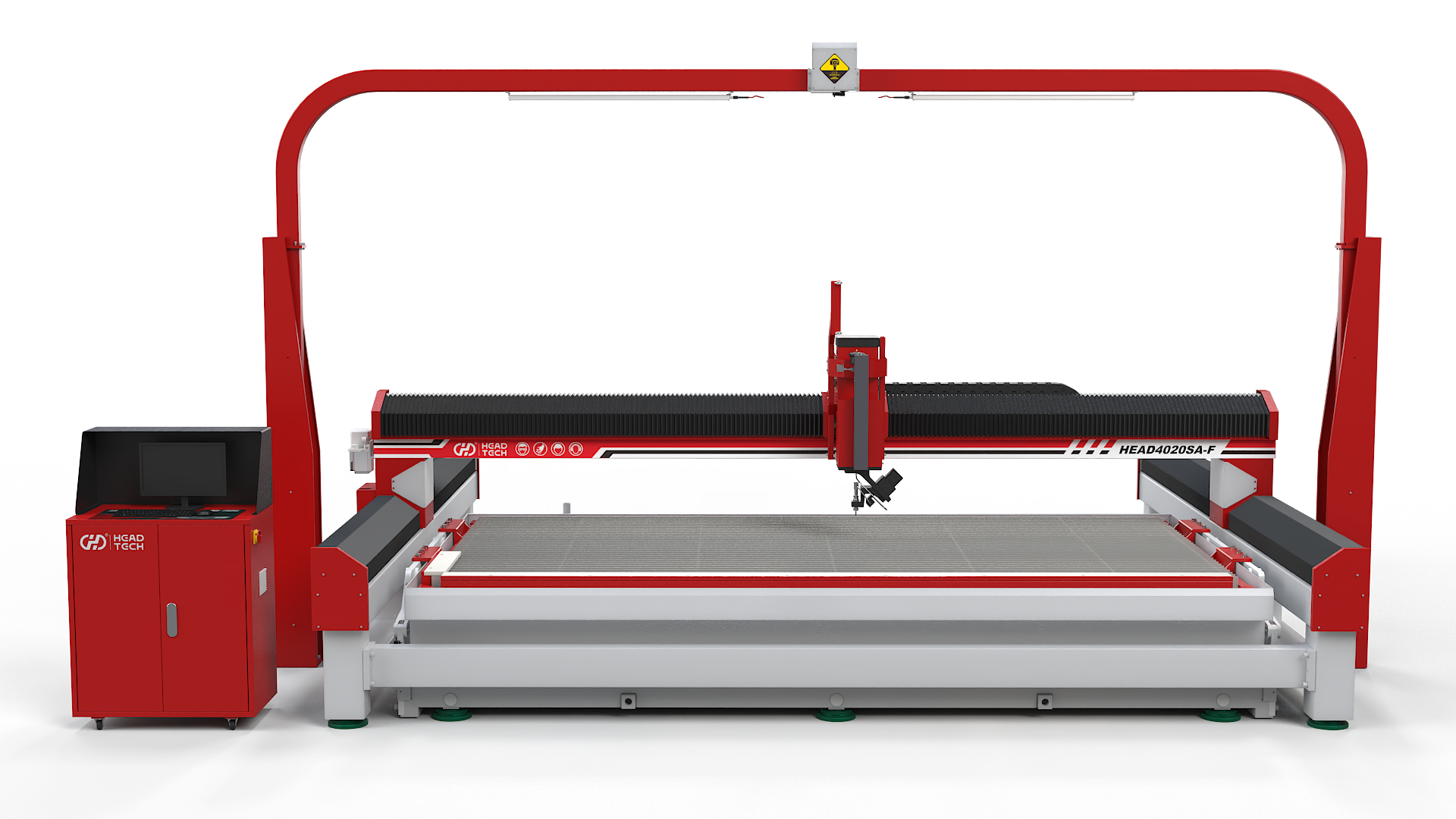

Our integrated workstation combines all essential processes into one seamless system: automatic vacuum loading, non-contact laser height scanning, cutting, and unloading—all within a single control platform. This eliminates inter-process delays and maximizes your factory’s productive time, allowing you to process more orders without increasing resources.

Your equipment is more than an asset—it’s an ongoing cost center. Cutting heads are particularly vulnerable to damage when working with uneven slabs or performing bevel cuts. Replacements are expensive, and downtime affects output.

The Challenge: Tool Crashes and Skilled Labor Shortages

Experienced operators are becoming harder to find. Inexperienced staff increase the risks of tool crashes, machine damage, and poor cut quality.

HEAD’s Solution:

Non-Contact Height Sensing: Our system automatically scans each slab’s surface before cutting and adjusts the Z-axis height in real time, keeping the cutting head at a safe distance from the material. This eliminates tool crashes entirely.

Simplified Operation: Our integrated system and user-friendly interface allow even new operators to quickly become productive after basic training. This reduces reliance on skilled labor and ensures consistent, stable production.

The key to profitability isn’t chasing more orders—it’s plugging the hidden cost drains in your workflow. Investing in a system that addresses these issues holistically is far more effective than patchwork fixes.

HEAD Waterjet’s integrated solutions are engineered with a deep understanding of the stone processing industry’s cost structure. Our equipment isn’t just a machine—it’s a strategic tool designed to improve your profitability and support long-term, sustainable growth.

Ready to turn your profit black holes into a growth engine?

Contact us : sale2@hdwaterjet.net for a customized ROI analysis for your factory.

content is empty!