- Home

- Customization Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-06-20 Origin: Site

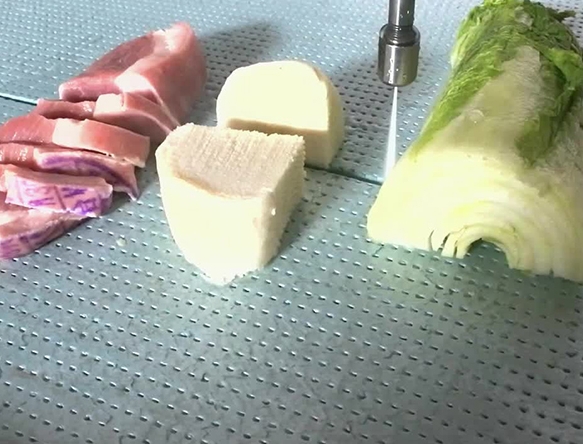

The modern baking industry operates at a crossroads of artistry and industrial efficiency. Consumers demand products that are not only delicious but also visually perfect and, increasingly, free from specific allergens. For bakeries, meeting these demands with traditional cutting equipment is a constant struggle that inevitably leads to waste in materials, labor, and time.

However, forward-thinking bakeries are discovering that the right technology can eliminate these compromises. This article details how a specialized HEAD Waterjet Cutting Food Machine is a catalyst for success, enabling bakeries to achieve new levels of quality, safety, and profitability.

For years, mechanical slicers and ultrasonic cutters were considered the standard. But our experience shows they create a production ceiling that bakeries now find unacceptable. The core issues are baked into the technology itself:

Sanitation & Food Safety Risks: Complex blade assemblies contain numerous crevices, bearings, and surfaces that are notoriously difficult to sanitize. This creates a high risk of bacterial growth and, critically, allergen cross-contamination.

Product Damage & Smearing: Even the sharpest blade makes contact. On delicate, multi-layered products like cheesecakes, mousses, or frosted cakes, this contact causes smearing between layers, destroying the visual appeal and leading to rejects.

Labor-Intensive Operation: These machines require constant monitoring, blade sharpening or replacement, and extensive, time-consuming cleaning protocols between batches—especially when switching between products with different ingredients (e.g., with nuts vs. nut-free).

To understand the transformative potential of new technology, let’s look at the case of "Artisan Layers Patisserie," a growing wholesale bakery specializing in premium cheesecakes and delicate layered desserts.

The Challenge:Artisan Layers built its brand on quality, but its growth was being throttled by its cutting process. Their two biggest challenges were:

Allergen Cross-Contamination: Their most popular cheesecake featured a pecan crust, but their fastest-growing market was for certified gluten-free and nut-free products. To avoid cross-contamination, they had to dedicate entire production days to allergen-free batches, followed by a 4-hour deep clean of their slicer. This created massive scheduling inefficiencies.

Aesthetic Rejects: Their mechanical slicer frequently smeared the raspberry filling into the cream cheese layer on their signature cheesecake, leading to an aesthetic rejection rate of nearly 8%. These products were sold at a steep discount, hurting their premium brand identity.

The Solution: The HEAD Waterjet Food MachineArtisan Layers invested in a HEAD Waterjet Cutting Food Machine, specifically chosen for its sanitary design and precision cutting capabilities. The machine, built with food-grade stainless steel and sealed components, was engineered to solve the exact problems they faced. The cutting medium is a micro-thin stream of pure, high-pressure water, controlled by a sophisticated CNC program.

The Results: A New Standard of OperationThe installation of the HEAD Waterjet machine delivered immediate, measurable, and game-changing results:

Cross-Contamination Risk Eliminated: The pure water jet leaves no residue. Artisan Layers could now switch from cutting a pecan-crusted cheesecake to a gluten-free dessert in the time it took to wash down the conveyor and load a new program—mere minutes. This eliminated the need for dedicated production days, increasing their operational flexibility by over 40%.

Perfect Aesthetics, Zero Smearing: The non-contact waterjet cut cleanly through every layer without dragging or smearing. Their aesthetic rejection rate dropped to zero. Every slice was flawless, boosting their brand image and making their products highly sought after by high-end cafes and retailers.

Labor Reallocated to Growth: The new process saved an estimated 15-20 hours of labor per week that was previously spent on deep cleaning the old slicer. This allowed them to reallocate skilled staff to product development and quality control.

Increased Capacity and Profit: The sheer speed and efficiency of the waterjet process allowed them to increase their total output by 30% within the same facility, directly boosting their bottom line.

The owner and head pastry chef of Artisan Layers commented: "The HEAD Waterjet machine is our food safety guarantee. It gives us the confidence to expand our allergen-free lines while still producing our classic recipes. The cut quality is simply unattainable with a blade. It's the centerpiece of our modern bakery."

A successful technology implementation relies on more than just hardware. Artisan Layers' success was also driven by the support they received. The on-site installation and training from HEAD's US-based technicians ensured their team was confident and proficient from the very first day. Knowing that expert support and a full inventory of parts are available domestically provides peace of mind and secures the long-term return on their investment.

Reading about success is one thing; creating your own is the next step. Our team is ready to help you analyze your current cutting process and identify your biggest opportunities for waste reduction and quality improvement.

Whether you are cutting frozen cakes, fresh bread, dessert bars, or confectioneries, we can provide a tailored solution. Reach out to our food application specialists today for a no-obligation consultation.

Visit Our Website: Fill out the contact form at www.headwaterjet.net or a detailed quote.

Email Our Expert Team: Send your questions or project specifications to sale2@hdwaterjet.net

Call Us Directly: Speak with a specialist by dialing 0086 15942048409.

Let us help you turn your cutting process into your greatest competitive advantage.

content is empty!