- Home

- Customization Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-16 Origin: Site

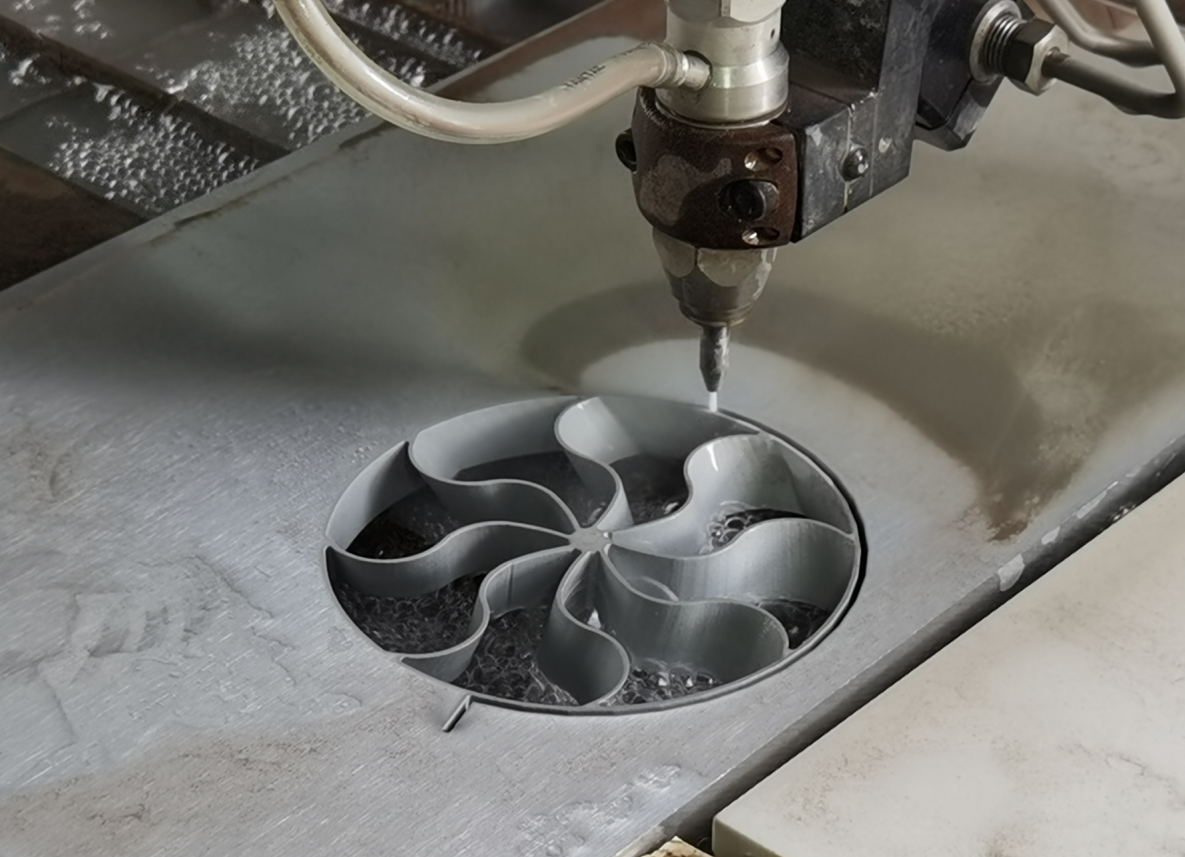

Water jet cutting is now one of the most trusted technologies for processing metals. By using a high-pressure stream of water mixed with garnet abrasive, it delivers clean, accurate cuts without heat or mechanical stress. For workshops in industries such as automotive, aerospace, stone & metal fabrication, and custom manufacturing, it offers a unique balance of speed, precision, and cost efficiency.

Unlike plasma or laser, waterjet is a cold process. It doesn’t change the temper of stainless steel, warp aluminium, or harden tool steel. That means fewer secondary operations like grinding or straightening — and parts maintain their original strength.

Case Example: A Monterrey-based automotive supplier replaced plasma with a HEAD 420 MPa waterjet to cut chassis brackets from 12 mm stainless steel. The result: zero warping and 30% less time spent on finishing.

Waterjets produce a smooth, satin-like edge with minimal striations. For precision engineering, this means parts often need no further deburring.

Case Example: A Querétaro aerospace shop uses a HEAD 5-axis system to cut 40 mm titanium plates. The clean edges allow immediate assembly, eliminating costly polishing.

From thin aluminium panels to 200 mm thick steel, a waterjet can handle it. HEAD’s pumps (420 MPa standard, up to 600 MPa) give Mexican manufacturers flexibility to quote a wider range of jobs.

Case Example: A countertop fabricator in Guadalajara uses a HEAD 3020BA machine to cut both 3 mm stainless splashbacks and 80 mm solid brass inlays with the same setup.

Water jet cutting achieves tolerances of ±0.1 mm or better. With optional 5-axis heads, you can bevel or create 3D profiles in steel, aluminium, copper, or exotic alloys.

Case Example: A specialist metal art studio in CDMX installed a HEAD 5-axis system to cut intricate copper panels for architectural facades — shapes impossible with saws or torches.

Because the kerf is narrow, you save raw material. HEAD’s nesting software arranges parts efficiently, helping reduce scrap by up to 15% compared with mechanical cutting.

Waterjet cutting doesn’t release toxic fumes or fine dust. Combined with HEAD’s optional abrasive recycling and water treatment, it supports greener production and cleaner workspaces.

There’s no cutting blade to overheat or dull. HEAD machines are designed with pyramid-style frames, sealed guides, and long-life pumps, ensuring stability and low downtime even in 24/7 operations.

Pressure & Performance: 420–600 MPa pumps deliver power for thin sheets or thick steel.

Flexible Solutions: 3-axis or 5-axis models, optional floor-type flipping frames for heavy plates.

Local Support in Mexico: Spare parts, online diagnostics, and Spanish-speaking technicians reduce downtime.

Cost-Effectiveness: Competitive price plus low running costs create one of the best ROI profiles in the market.

Proven Track Record: From aerospace parts to decorative stainless screens, Mexican clients report consistent accuracy and strong after-sales service.

For workshops cutting steel, aluminium, titanium, brass, or copper, water jet technology offers unmatched flexibility, accuracy, and quality. By partnering with a supplier like HEAD Waterjet, Mexican businesses gain precision equipment, robust service, and competitive ownership costs — a smart move for anyone wanting to expand capacity and deliver superior metal parts.

Email: sale2@hdwaterjet.com

WhatsApp: 0086 15942048409

content is empty!