- Home

- Customization Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-15 Origin: Site

When European manufacturers, engineers, and procurement managers research waterjet cutting systems, two technical specs become critical: pump type and operating pressure.

These determine cost, accuracy, maintenance, and compliance with safety and industrial regulations.

Here’s a guide to help you make an informed choice.

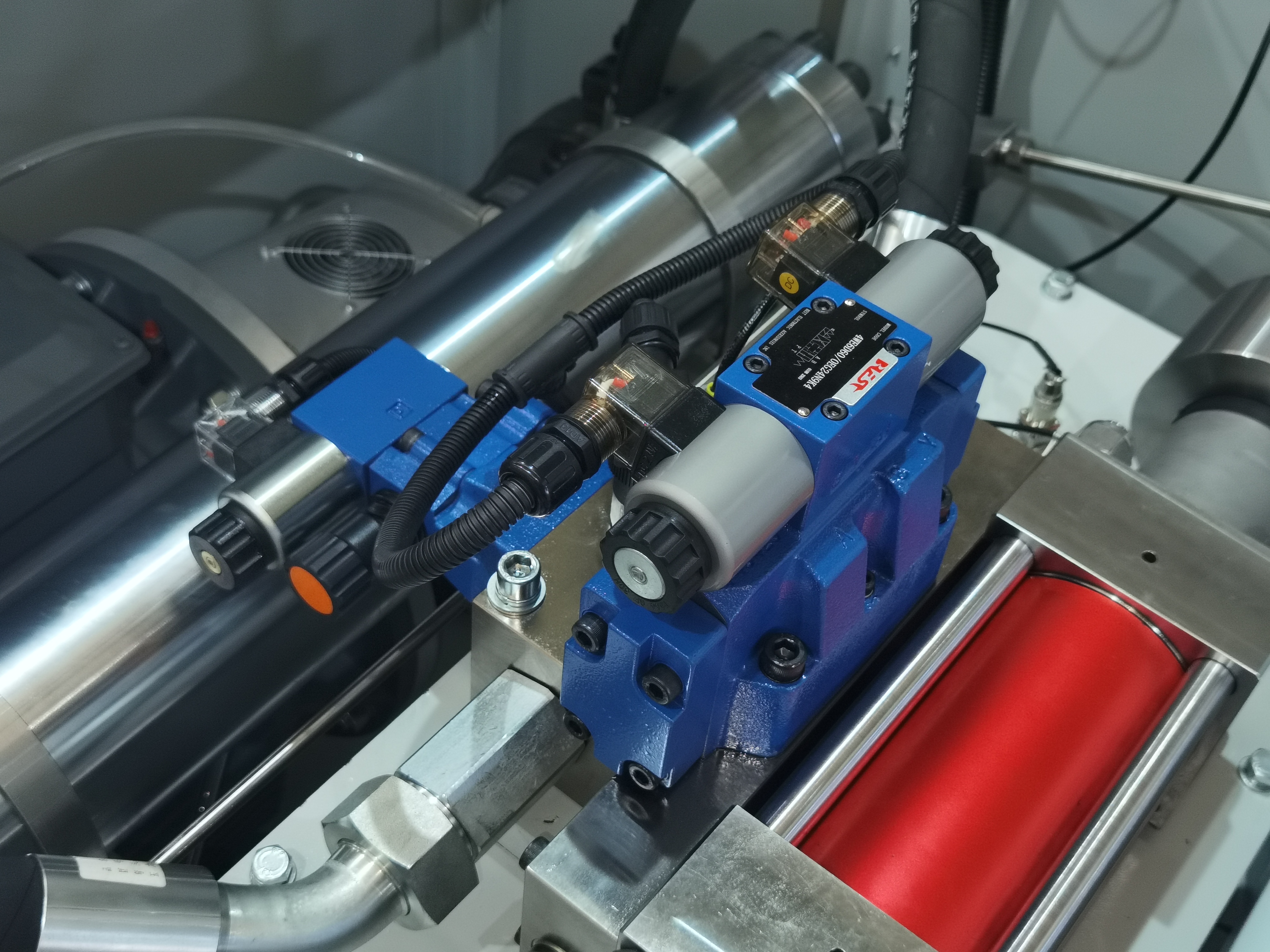

There are two main types of high-pressure pumps in waterjet technology: hydraulic intensifier pumps and direct-drive (triplex crank) pumps.

Intensifiers use hydraulics to convert low-pressure oil into very high-pressure water, typically producing pressures above ~60,000 psi (≈4,100 bar / ≈410 MPa). Advantages include the ability to power multiple cutting heads, higher maximum pressure, longer service intervals, and stable pressure under varying load.

Direct-drive pumps use a crankshaft with pistons to generate ultrahigh pressure. They are usually more energy-efficient, have fewer hydraulic parts, run quieter, and cost less upfront. However, they are generally limited to ~60,000 psi and may need more frequent maintenance for heavy-duty or continuous work.

The pressure rating (psi, bar, or MPa) is a key performance metric. Higher isn’t always better—match the pressure to your material, thickness, and desired edge quality.

| Pressure Range | Common Use-Cases | Advantages | Trade-Offs |

|---|---|---|---|

| 30,000–50,000 psi (~2,000–3,500 bar / ~210–350 MPa) | Softer metals (aluminium, mild steel), thin sheet metals, plastics, composites | Lower wear, reduced consumable cost, quieter | Slower on very thick or hard materials |

| 50,000–60,000 psi (~3,500–4,100 bar / 350–410 MPa) | General metal and stone cutting, moderate thickness | Good balance of speed, precision, abrasive efficiency | Higher upfront cost; requires careful cooling and maintenance |

| 60,000+ psi (Hyperpressure) | Very thick or hard metals, thick stone, specialised jobs | Faster cuts, less abrasive per metre, improved edge quality | High capital cost, more frequent service, strict EU safety standards |

Maintenance & Parts: Intensifier pumps, while pricier initially, often save money long term thanks to durability. Direct-drive pumps are simpler for light or medium production.

Energy & Total Cost: Account for electricity, abrasive, water, and downtime. Higher pressure may reduce abrasive use, but hyperpressure pumps consume more energy and wear components faster.

Compliance & Safety: Ensure pumps meet EU standards such as PED, the Machinery Directive, and EN/ISO safety codes.

Applications: Match pressure and pump type to materials, thickness, finish, and whether you need multiple heads or bevel cutting.

For most European shops cutting metals, stone, or composites, a 50,000–60,000 psi intensifier offers the best balance of productivity, precision, and lifetime cost. For ultra-thick or hard materials, hyperpressure may improve speed, but expect higher operating and service costs. If your budget is smaller or volumes lower, a direct-drive pump is a good entry-level choice.

Always request test cuts on your materials to verify performance. Ask about seal life, service intervals, and parts availability in Europe. Confirm CE certification and EU compliance, and evaluate the total cost of ownership: purchase price, energy, abrasive, and downtime.

```

content is empty!