- Home

- Customization Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-15 Origin: Site

For manufacturers, engineers, and designers, the key question before investing in new cutting technology is simple:

“Can it handle our specific materials and dimensions?”

With abrasive waterjet cutting, the answer is almost always a resounding yes.

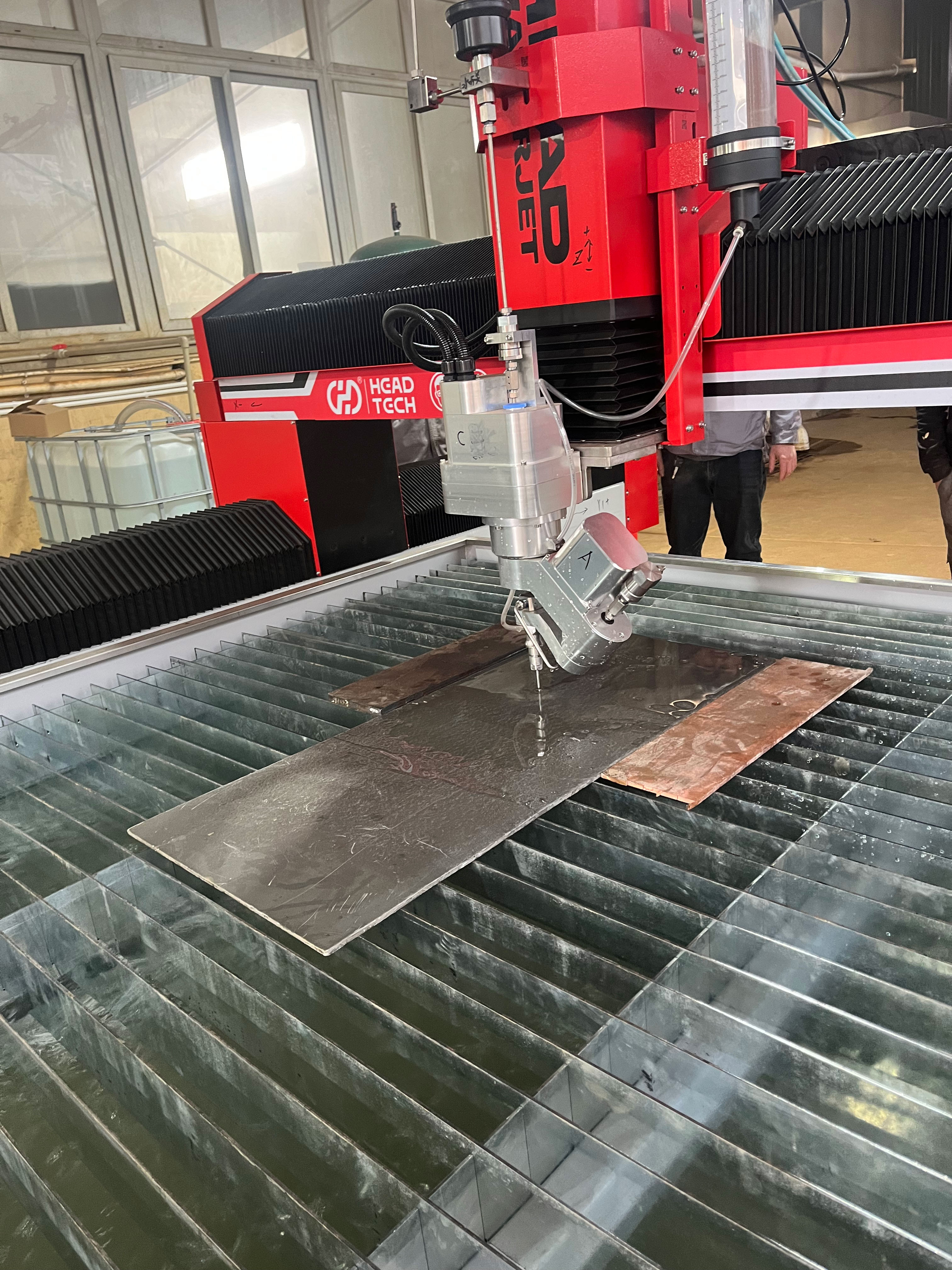

A waterjet’s cold-cutting process — using a high-pressure stream of water mixed with garnet abrasive — delivers unmatched versatility. Unlike lasers or plasma cutters that rely on heat, a waterjet cuts by supersonic erosion, avoiding heat-affected zones (HAZ), mechanical stress, or toxic fumes.

Waterjets excel in metal fabrication thanks to their non-thermal process.

Steel: From mild to stainless and hardened tool steel, waterjets achieve smooth edges up to 4 inches (~100 mm); thicker sections (up to 10 in / 250 mm) are possible for specialised jobs.

Aluminium: Easily cut up to 6 in (~150 mm) while maintaining structural integrity.

Titanium & Exotic Alloys: Ideal for titanium, Inconel, and Hastelloy, preserving material properties without work-hardening.

Copper & Brass: Clean, efficient cutting without issues from reflectivity.

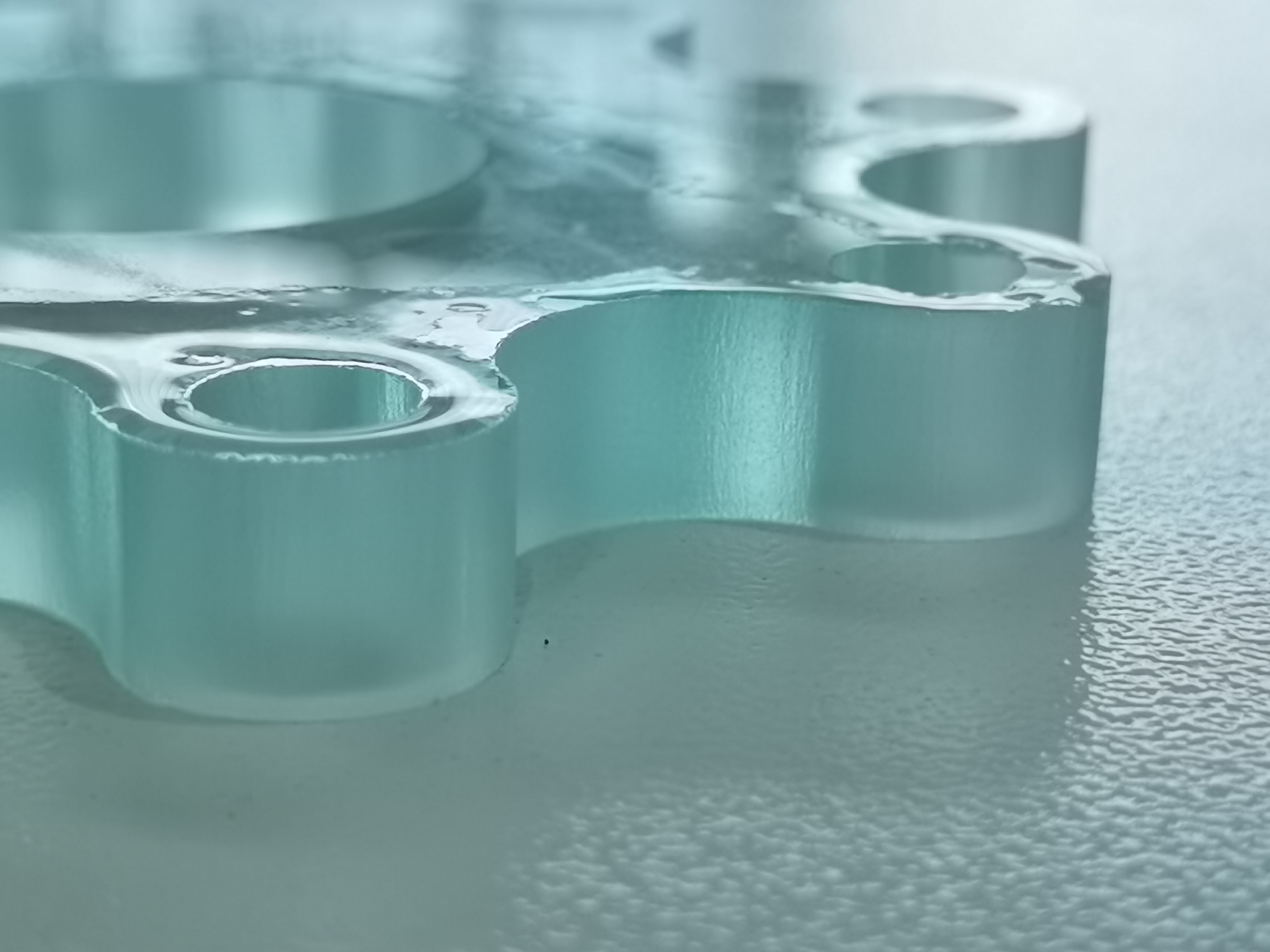

A waterjet’s low-pressure piercing and non-contact stream protect delicate materials from cracking or chipping.

Granite, Marble & Quartz: Perfect for countertops, inlays, and architectural work up to ~75 mm thick.

Ceramic & Porcelain Tile: Accurate cuts for mosaics, medallions, and sharp corners.

Concrete: Shapes panels and pavers for architectural or decorative use.

With the right settings, waterjets cut glass safely. A low-pressure pierce prevents shattering, then full pressure completes the cut.

Handles sheet glass, mirrors, laminated, and bullet-resistant glass in a single pass — though tempered glass cannot be cut as it is designed to shatter.

Waterjets solve the challenges of modern composites by cutting without heat.

Carbon Fibre & CFRP: Trim aerospace or automotive parts cleanly, without dust or delamination.

Fibreglass & G10: Smooth edges for boats, circuit boards, and more.

Plastics & Acrylics: From soft foam to acrylic or polycarbonate, cuts are clean and burr-free.

Practical cutting limits depend on three factors: pump pressure, abrasive flow, and desired edge quality.

Higher pressure and abrasive rates improve speed and thickness capability, while slower feed rates produce finer, taper-free edges.

A single waterjet can handle jobs from 1/4″ aluminium to 4″ titanium — versatility unmatched by other cutting methods.

content is empty!