- Home

- Customization Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-28 Origin: Site

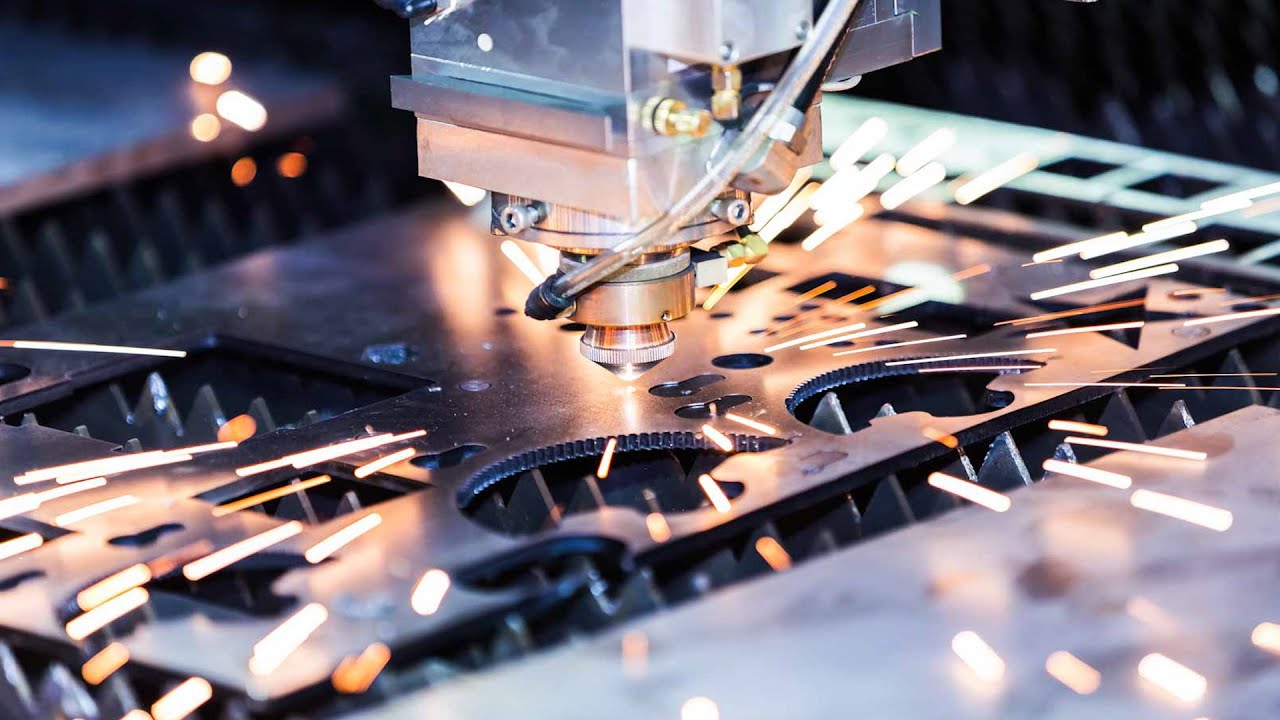

Metal fabrication teams today are asked to deliver tight-tolerance parts, faster lead times, and lower total cost—often across mixed materials like stainless, aluminum, copper, and composites. Laser and plasma remain popular for speed, but their heat-affected zones (HAZ), consumable burn, and material limits are increasingly at odds with customer expectations. This guide explains why shops worldwide are adopting HEAD Waterjet—and how to quantify the quality, cost, and capacity gains in your own operation.

Heat distortion & metallurgy changes: Thin stainless or aluminum can warp; edges harden and complicate tapping or welding.

Material constraints: Plasma is limited to conductive metals; lasers struggle with highly reflective alloys and layered stacks.

Edge quality & rework: Dross and HAZ often require grinding, adding labor and schedule risk.

Consumables & downtime: Nozzles, electrodes, optics, and shielding add volatile OPEX and frequent stops.

HSE burden: Fumes, UV, and noise drive ventilation and compliance costs.

Waterjet removes material with high-pressure water and abrasive—no heat. Parts retain base-metal properties with burr-free edges, ready for downstream forming, welding, coating, or assembly.

Zero HAZ, zero warping: Protects stainless, aluminum, copper, brass, and heat-sensitive alloys.

±0.1 mm accuracy: Supports precision brackets, panels, slots, and small holes.

True multi-material: Cut metals and composites, rubber, plastics, glass, and stone on one platform.

Lower rework: Clean edges reduce grinding/deburring and fixture time.

Predictable cost-per-part: OPEX centers on abrasive + water + energy—stable and forecastable.

A mid-size shop producing food-grade stainless panels replaced a legacy plasma cell with a HEAD waterjet. In 12 months, they reported:

−40% rework from burr-free edges; grinding operations were eliminated on most SKUs.

+15% material yield via thin kerf and optimized nesting.

New revenue from aluminum and composite parts that previously required outsourcing.

~20% profit uplift after stabilizing cost-per-part and shortening lead times.

Match nozzle ID and abrasive mesh (80#–120# typical) to thickness and finish. Use short DOE trials to balance edge finish, cut speed, and abrasive consumption.

Ramped/low-pressure pierce and off-feature lead-ins keep witness marks out of functional edges; staged pierces protect thin or clad materials.

Common-line cutting, micro-tabs, and minimized traverses reduce cycle time. If available, dual-head synchronization halves takt on repeat nests.

Stable slats and tank damping keep sheets flat, improving tolerance on fine features (slots, small holes, tight radii).

Edge quality: Waterjet = burr-free, no HAZ; Laser = crisp but heat-affected; Plasma = fast but dross prone.

Materials: Waterjet = metals + non-metals; Laser/Plasma = primarily metals.

Tolerance: Waterjet excels on mixed thickness and tight radii without heat shift.

OPEX: Waterjet = predictable abrasive/water; Laser/Plasma = optics/electrodes/nozzles variability.

HSE: Waterjet runs cooler/quieter with no fume UV load.

20+ years of R&D: Industrial waterjet expertise across metal, stone, glass, and composites.

Global footprint: Installations in 80+ countries with training and lifetime service.

Configurable platforms: From compact tables (e.g., HEAD1020BB) to large gantry and 5-axis/robotic cells.

Customer loyalty: Repeat orders in Europe, Asia, and the Americas confirm reliability and ROI.

Baseline: Capture current rework hours, consumable spend, and scrap.

Pilot parts: Select high-volume SKUs; run sample cuts to compare edge quality and takt.

Cost model: Convert to cost-per-meter with abrasive/water/energy; include rework avoidance.

Scale plan: Standardize CAM templates; train operators; add shifts or dual heads as demand grows.

Eliminate heat distortion and reduce rework with cold waterjet cutting.

Gain ±0.1 mm accuracy and burr-free edges ready for assembly.

Expand into multi-material work without new platforms.

Stabilize OPEX and increase margins with predictable cost-per-part.

Considering a shift from laser/plasma to waterjet—or adding a mixed-material cell? Share your drawings and target takt time. HEAD engineers will run sample cuts and model ROI using your parts and volumes.

Website: www.headwaterjet.net

Email: sale2@hdwaterjet.com

WhatsApp: +86 15942048409

HEAD Waterjet – Cutting Beyond Limits, Creating More Value for Metal Fabrication.

content is empty!