- Home

- Customization Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

HEAD

HEAD

HS code: 84565000

| Availability: | |

|---|---|

Product Description

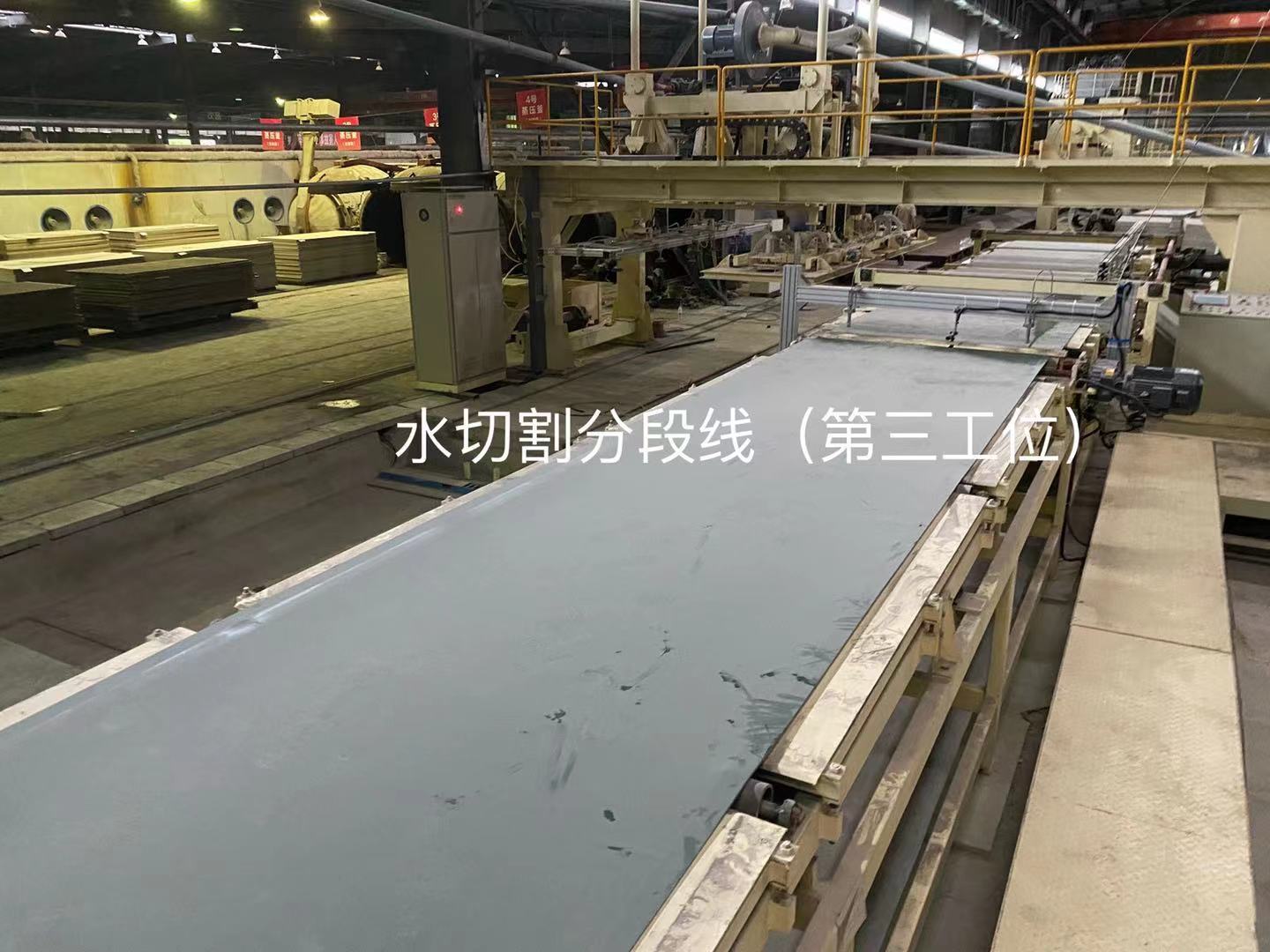

A horizontally movable cross-cutting waterjet nozzle is installed on the beam, and the top of the base is fixed with a vertical-cutting waterjet nozzle. Two vertical-cutting waterjet nozzles and three cross-cutting waterjet nozzles are arranged in order along the conveying direction of the cutting and conveying device. , And two slitting waterjet nozzles and three crosscutting waterjet nozzles are all connected to a high-pressure water main engine with a working water pressure of 100Mpa~420Mpa, and two slitting waterjet nozzles and three crosscutting waterjet nozzles are all set in There is a diamond nozzle, and the diameter of the water jet hole of the diamond nozzle is 0.2mm~0.35mm.

The pure water water jet cutting calcium silicate board assembly line reduces dust pollution, reduces slab turnover, improves the qualification rate, reduces equipment costs, and reduces energy consumption.

Because the HD Waterjet high-pressure pump can provide stable high-pressure water, the production line cuts the plate faster than before, and the incision is very smooth. Multiple cutter heads can work at the same time to cut the plate with a thickness of more than 20 mm. At the same time, the noise generated by the equipment is significantly reduced, and the dust is greatly reduced. This solution has successfully reduced the production cost, improved the cutting efficiency, improved the workshop environment, and fully achieved the design purpose.Because the HD Waterjethigh-pressure pump can provide stable high-pressure water, the production line cuts the plate faster than before, and the incision is very smooth. Multiple cutter heads can work at the same time to cut the plate with a thickness of more than 20 mm. At the same time, the noise generated by the equipment is significantly reduced, and the dust is greatly reduced. This solution has successfully reduced the production cost, improved the cutting efficiency, improved the workshop environment, and fully achieved the design purpose.