- Home

- Non-standard Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

HEAD1520BB

HEAD

hs code:84565000

| Availability: | |

|---|---|

Product Description

Keeping track of latest market development we are actively engaged in offering CNC Water Jet Cutting Machine. Widely used for cutting soft & hard materials, the offered jet cutting machine is good demand in the market for its high performance. In order to assure the quality, the complete range of jet cutting machine is checked on numerous parameters before the final delivery at the customer’s end. The offered jet cutting machine is provided with different specifications at affordable price.Our experience in the water jet industry has allowed us to include the small details that will save you time and money in the long run. All our machines are built and sold with the following features

50 HP High 420 MPa pressure for smooth finish cutting at high speed.

Main heart of Supercharger, "Intensifier" is "Made in USA".

User friendly & minimum maintenance cutting head design with USA make "Water Switch Seal Kit" & other parts.

All parts of machine are processed on Highly accurate servo motor (made in Japan). Which gives you trouble free operation & long life of parts.

Separate body between cutting table and load-bearing platform prevents interfering cutting accuracy from long-term stress variation to load-bearing platform.

X beam of cutting table applies the one-off extrusion forming aluminum alloy, light weight, strong steel, not deformed, is the most advanced technology .

Cancelling dustproof cloth on X, Y, Z axis and hiding Y axis towline greatly improve the machine life and save the maintenance cost.

Motor and ball screw are directly connected by flexible coupling. It can absorb vibration energy reversible and with higher drive accuracy compared with other torsional rigid coupling.

Using high-quality international brand ball screw, linear guide transmission structure to ensure the moving speed and accuracy of the cutting head.

The cutting head is with casting structure and concrete structure. The metal parts have been specially processed to eliminate traces of deformation and to maintain long-term mechanical precision.

| Max.cutting range(mm) | 1500*2000mm |

| Running speed | 6000mm/min |

| Travel of Z axis | 150mm |

| Repeat positioning accuracy | ±0.025mm/m |

| Control accuracy | ±0.01mm |

| Cutting accuracy | ±0.1mm |

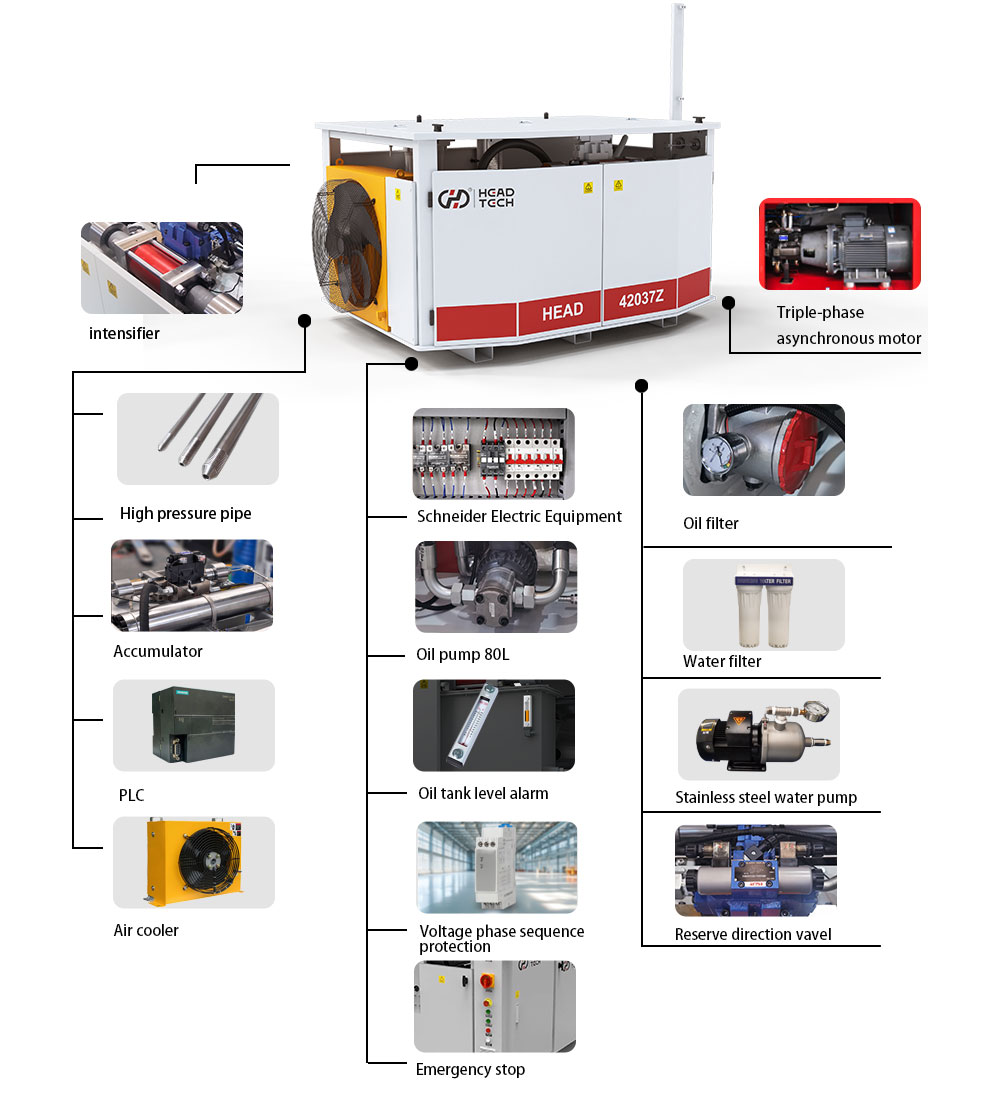

High Pressure Pump

| Rated pressure | 420Mpa(60000psi) |

| Working pressure | 50-380MPa(7200-55000psi) |

| Main motor power | 37KW(50hp) |

| Air cooler power | 0.78KW |

| Dimensions | 1900*1350*1100 |

| Weight | 1.3T |

| Maximum displacement | 3.7L/min |

| Pressure ratio | 1:20 |

| Maximum oil pump flow | 119L/min |

| High-pressure water pipe specifications | Φ3/8" |

Liquid-to-liquid boosting technology: stable and efficient pressure increase, imported parts guarantee long-term stability, worry-free operation!

Military-grade material: made of 316L seamless steel pipe, anti-yield, anti-stretching, corrosion-resistant, durability increased by 50%!

Extremely long maintenance-free: innovative "TDM" accumulator, life span exceeds 5000 hours, save worry, labor and money!

Large-capacity buffer: 1.2-liter accumulator, reduce pressure loss, increase efficiency by 20%!

Cooling device helps high pressure pump work better in hot places

Beide brand motor: cast iron body, 10% energy saving, low noise and low vibration, rock-solid performance!

80 pump super large flow: 119L/min super power, reduce pipeline resistance, efficiency soared by 30%!

ISO international standard oil pipe: resistant to pressure and fluctuation, leading system stability in the industry!

Intelligent high and low pressure switching: adapt to different materials, finer cutting, 50% reduction in roughness! (Exclusive for A25+ version)

Double insurance for pressure relief: high and low pressure water pressure relief valve, no dead angle for safety protection! (A25+ version optional)

7 kinds of intelligent protection:fault alarm, oil temperature monitoring, low pressure shutdown, motor protection, liquid level warning, filter element blockage warning, phase sequence protection, all-round protection of equipment!

Automatic shutdown mechanism: abnormal situation response in seconds, equipment damage risk is zero!

Our Service

What we provide: Professional machine installation and commissioning by certified engineers, followed by systematic training for your operators, programmers, and maintenance staff.

Your Benefits:

Peak Performance from Day One: Ensures the equipment operates under ideal conditions from the start, avoiding accuracy issues or potential failures caused by improper setup.

Empowered Team: Your operators learn to use the machine safely and efficiently, reducing material waste and preventing damage from user error, thereby maximizing productivity.

In-House First Response: Your team will be equipped to handle routine maintenance and basic troubleshooting, reducing reliance on service calls and saving time and money.

What we provide: 24/7 or extended business-hour support via hotline, online chat, or video, equipped with powerful remote diagnostic capabilities.

Your Benefits:

Instant Problem Solving: Simple issues are resolved immediately through expert guidance, eliminating waiting times.

Precise Remote Diagnostics: Our technical team can remotely access your machine's system to quickly pinpoint the root cause of a problem, whether it's software, parameters, or hardware. Over 80% of issues can be solved remotely, drastically reducing downtime.

Reduced Service Costs: Avoids unnecessary on-site visits, directly saving you travel and labor expenses.

What we provide: Local or regional parts centers stocked with high-quality, original (OEM) consumables and spare parts like garnet, nozzles, mixing tubes, and high-pressure seals.

Your Benefits:

Fast Access to Critical Parts: Key components can be delivered within 24-48 hours, preventing long production halts while waiting for parts.

Guaranteed Cutting Quality: Using genuine OEM parts ensures optimal cutting performance and precision while extending the life of associated components, leading to a lower total cost of ownership.

Simplified Procurement: A one-stop shop for quality-assured parts means you don't waste time and resources sourcing and testing inferior alternatives.

What we provide: Scheduled Preventive Maintenance (PM) contracts and, when necessary, rapid dispatch of certified field engineers for on-site service.

Your Benefits:

Extended Equipment Lifespan: Regular maintenance identifies and resolves potential issues before they become major failures, significantly extending the machine's life.

Predictable Downtime: Schedule maintenance during planned production breaks instead of suffering unexpected, costly breakdowns during peak times.

Efficient & Effective Repairs: When a site visit is necessary, engineers arrive informed by remote diagnostics and equipped with the correct parts to solve the problem on the first visit.

What we provide: Regular software updates, hardware upgrade paths (e.g., to a 5-axis cutting head or a higher-pressure pump), and process optimization consulting.

Your Benefits:

Future-Proof Technology: Access the latest cutting technologies and efficiency improvements

Customer Reviews