- Home

- Customization Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

HEAD1020BB

HEAD

hs code:84649011

| Availability: | |

|---|---|

Product Description

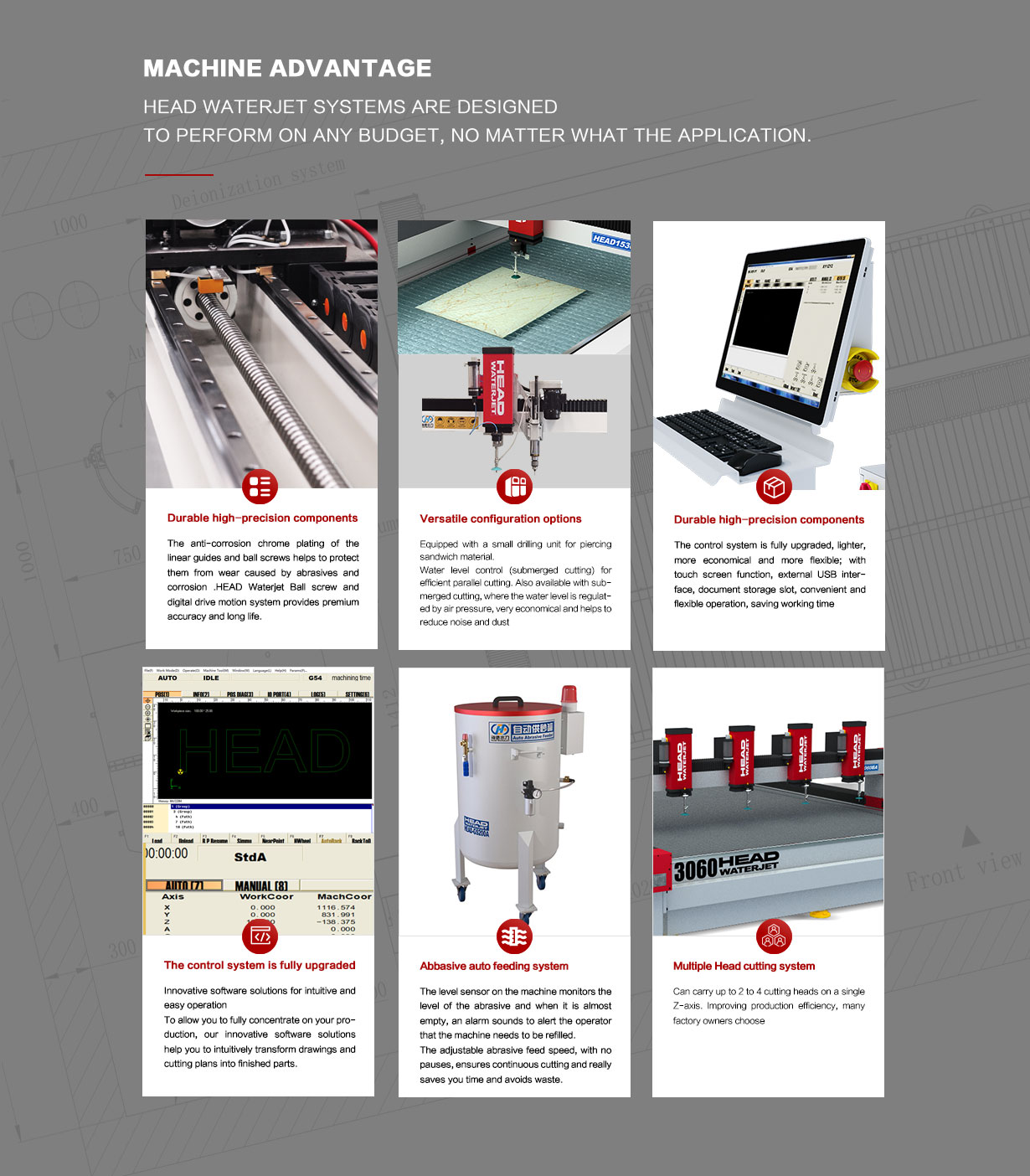

Cutting materials are not limited (stainless steel, steel, copper, aluminum and other metals, glass steel, stone, glass, ceramics, plastics, composite materials...), waterjet cutting is currently the most applicable cutting process;

No heat is generated during cutting, no arc marks appear at the slits, no thermal effect, no need for re-machining and easy rework;

It can cut and punch any curve, no need for mold, flexible and convenient;

The slit is only 1-1.5, the cut surface is smooth and smooth, and the roughness can reach 3.2μm~1.6μm;

The workpiece does not need special clamping, and the operation is simple and convenient;

The cutting range is wide and the thickness of the metal is up to 150mm

• 50 HP High 420 MPa pressure for smooth finish cutting at high speed.

• Main heart of Supercharger, "Intensifier" is "Made in USA".

• User friendly & minimum maintenance cutting head design with USA make "Water Switch Seal Kit" & other parts.

• All parts of machine are processed on Highly accurate YASKAWA servo motor (made in Japan). Which gives you trouble free operation & long life of parts.

| SPECIFICATIONS FOR WATER JET CUTTING MACHINE | |||

| Max. pressure | 380-420MPA | ||

| Max. flow rate | 3.7L / min | ||

| Electrical source voltage | 3 phases 220/380 Voltage, 50/60Hz, 37KW, 50HP | ||

| Max. diameter of nozzle / orifice | 1.02mm / 0.33mm | ||

| Max. delivery capacity of oil pump | 106L / min | ||

| Max cutting heads | 1-10 cutting heads (1 for standard machine) | ||

High Pressure Pump

Unique design of this water jet cutting machine makes the installation and the maintenance easier.Stable working pressure to ensure the working efficiency.

Designed & manufactured to perfection, we are one of the well known and leading manufacturers and exporters of Water Jet Cutting Machinery. At our premises, we are manufacturing the cutting machinery utilizing premium quality of raw materials and components. In addition to this, the cutting machinery is best known in the market due to its remarkable features such as high performance, easy operation and durability. This Machinery finds usage in many application such as automotive, aerospace and electronics for cutting metals and non metals.

Packing Delivery

Machine packing inside is plastic films and outside is fumigation wooden case. Our wooden case is very strong,it can bear long time shipping on the sea.And machine with preservative film,it can stop the salt sea water enter into the machine and make the machine corrosion.

Air freight, Ocean freight, land freight and other ways.

Payment methods: