- Home

- Customization Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

HEAD4020SA

HEAD

| Availability: | |

|---|---|

Product Description

Advanced Bellows Protection: A fully sealed, internally sloped design eliminates water and debris buildup, preventing corrosion and dramatically extending the machine's lifespan.

Enhanced Cutting Accuracy: Reinforced guide rails with high-rigidity press blocks ensure superior stability, delivering consistent, micron-level precision on every cut.

Rapid-Maintenance Design: An integrated cable management system and external abrasive hose with quick-connect fittings allow for faster diagnostics and tool-free parts replacement, minimizing downtime.

Eco-Friendly Oil Recovery: The directional lubrication and oil recovery system prevents contamination, ensuring a cleaner work environment and reducing operational costs.

Technical Parameters

| Platform structure | Model | X-axis travel | Y-axis travel | Z-axis travel | Water tank height | Water tank load | Maximum idling speed | Cutting accuracy | Positioning accuracy | Repeat positioning accuracy | |

| Gantry | Monoblock | HEAD-2015MA | 2000mm | 1500mm | 150mm | 900mm | 500KG/㎡ | 9m/min | ±0.1mm | ±0.05mm/500mm | ±0.03mm/500mm |

| HEAD-2515MA | 2500mm | 1500mm | 150mm | 900mm | 500KG/㎡ | 9m/min | ±0.1mm | ±0.05mm/500mm | ±0.03mm/500mm | ||

| Separate | HEAD-2030SA | 2000mm | 3000mm | 150mm | 750mm | 500KG/㎡ | 9m/min | ±0.1mm | ±0.05mm/500mm | ±0.03mm/500mm | |

| HEAD-2060SA | 2000mm | 6000mm | 150mm | 750mm | 500KG/㎡ | 9m/min | ±0.1mm | ±0.05mm/500mm | ±0.03mm/500mm | ||

| HEAD-3020SA | 3000mm | 2000mm | 150mm | 750mm | 500KG/㎡ | 9m/min | ±0.1mm | ±0.05mm/500mm | ±0.03mm/500mm | ||

| HEAD-3060SA | 3000mm | 6000mm | 150mm | 750mm | 500KG/㎡ | 9m/min | ±0.1mm | ±0.05mm/500mm | ±0.03mm/500mm | ||

| HEAD-4020SA | 4000mm | 2000mm | 150mm | 750mm | 500KG/㎡ | 9m/min | ±0.1mm | ±0.05mm/500mm | ±0.03mm/500mm |

Cutting Platform

X-axis one-piece extrusion molding, long-term stability

Split platform water tank to reduce maintenance costs

Programmable Z-axis, capable of meeting different process requirements

High-strength grille, no deformation under heavy load

Adopts integrated inward-tilted dustproof folding cloth to achieve all-round protection and automatic drainage

The pyramid-style weight distribution makes the base more stable than the top of the tower, ensuring that the center of gravity is close to the ground. Even at high speeds, the entire machine is as stable as a rock.

1. Adopting an integrated inward sloping dust-proof folding cloth, splashing water will flow downwards, making it less likely to accumulate water. The fully protective sealing structure follows the international cutting-edge design concept, significantly extending the service life of the machine tool, effectively reducing maintenance costs, and leading the mainstream trend of the water cutting machine industry

2. Design oil guide holes on the frame and equip them with bottom collection devices to effectively prevent the accumulation of lubricating oil from affecting the accuracy of the screw, while also facilitating the centralized cleaning and maintenance of waste oil.

3. Adopting a dedicated industrial control computer, equipped with Intel processor, 4GB memory, 128GB solid-state drive, and installed with Windows 10 operating system. The overall stability of the machine is higher than that of a personal computer.

4. Select high-quality reinforced fully enclosed machine tool drag chains, use high-quality nylon raw materials, have a solid structure, withstand extreme temperatures, and ensure long-term service. Effectively protect cables from damage. The surface of the drag chain is smooth and stable, reducing resistance and friction with the trachea, running quietly, and supporting high-speed continuous operation.

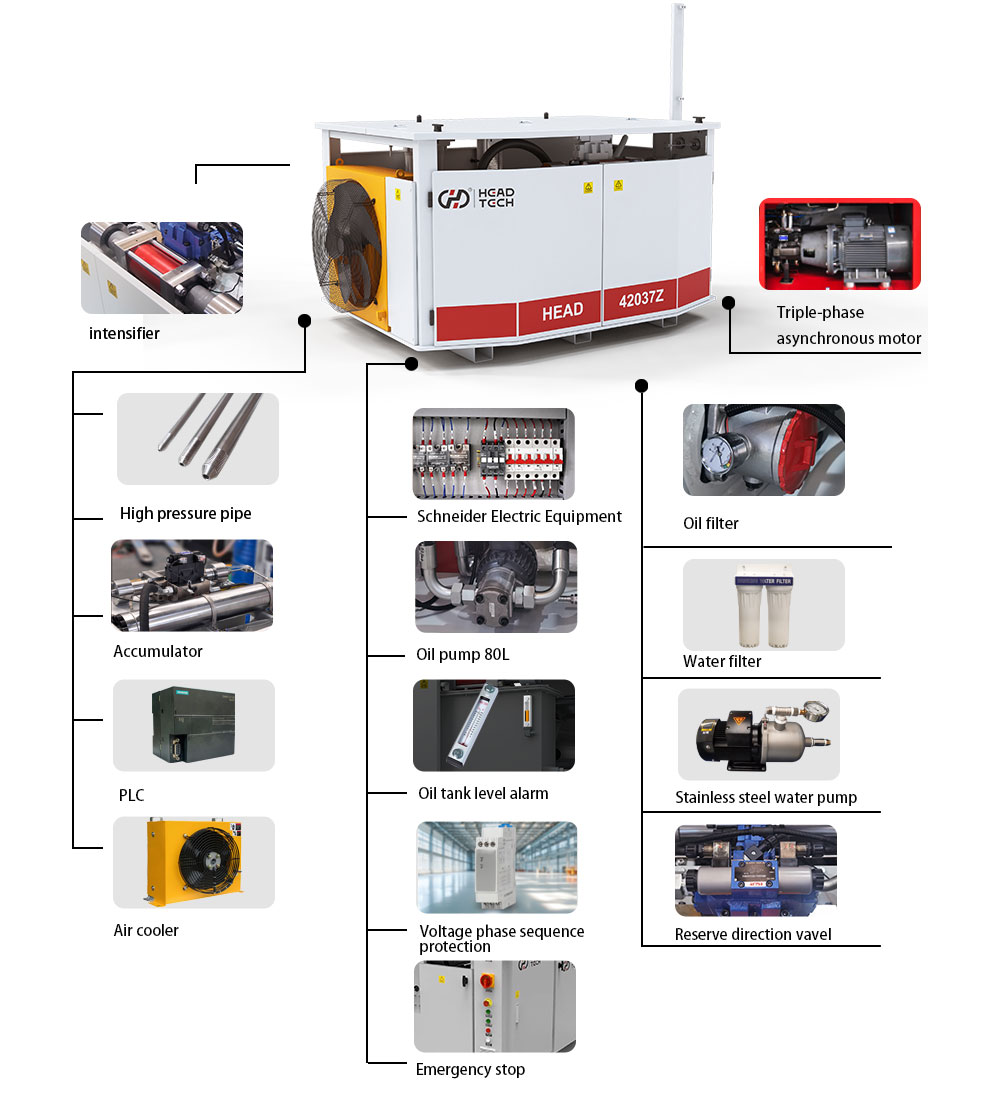

High Pressure Pump

| Rated pressure | 420Mpa(60000psi) |

| Working pressure | 50-380MPa(7200-55000psi) |

| Main motor power | 37KW(50hp) |

| Air cooler power | 0.78KW |

| Dimensions | 1900*1350*1100 |

| Weight | 1.3T |

| Maximum displacement | 3.7L/min |

| Pressure ratio | 1:20 |

| Maximum oil pump flow | 119L/min |

| High-pressure water pipe specifications | Φ3/8" |

Liquid-to-liquid boosting technology: stable and efficient pressure increase, imported parts guarantee long-term stability, worry-free operation!

Military-grade material: made of 316L seamless steel pipe, anti-yield, anti-stretching, corrosion-resistant, durability increased by 50%!

Extremely long maintenance-free: innovative "TDM" accumulator, life span exceeds 5000 hours, save worry, labor and money!

Large-capacity buffer: 1.2-liter accumulator, reduce pressure loss, increase efficiency by 20%!

Beide brand motor: cast iron body, 10% energy saving, low noise and low vibration, rock-solid performance!

80 pump super large flow: 119L/min super power, reduce pipeline resistance, efficiency soared by 30%!

ISO international standard oil pipe: resistant to pressure and fluctuation, leading system stability in the industry!

Intelligent high and low pressure switching: adapt to different materials, finer cutting, 50% reduction in roughness! (Exclusive for A25+ version)

Double insurance for pressure relief: high and low pressure water pressure relief valve, no dead angle for safety protection! (A25+ version optional)

7 kinds of intelligent protection:fault alarm, oil temperature monitoring, low pressure shutdown, motor protection, liquid level warning, filter element blockage warning, phase sequence protection, all-round protection of equipment!

Automatic shutdown mechanism: abnormal situation response in seconds, equipment damage risk is zero!

Our Service

What we provide: Professional machine installation and commissioning by certified engineers, followed by systematic training for your operators, programmers, and maintenance staff.

Your Benefits:

Peak Performance from Day One: Ensures the equipment operates under ideal conditions from the start, avoiding accuracy issues or potential failures caused by improper setup.

Empowered Team: Your operators learn to use the machine safely and efficiently, reducing material waste and preventing damage from user error, thereby maximizing productivity.

In-House First Response: Your team will be equipped to handle routine maintenance and basic troubleshooting, reducing reliance on service calls and saving time and money.

What we provide: 24/7 or extended business-hour support via hotline, online chat, or video, equipped with powerful remote diagnostic capabilities.

Your Benefits:

Instant Problem Solving: Simple issues are resolved immediately through expert guidance, eliminating waiting times.

Precise Remote Diagnostics: Our technical team can remotely access your machine's system to quickly pinpoint the root cause of a problem, whether it's software, parameters, or hardware. Over 80% of issues can be solved remotely, drastically reducing downtime.

Reduced Service Costs: Avoids unnecessary on-site visits, directly saving you travel and labor expenses.

What we provide: Local or regional parts centers stocked with high-quality, original (OEM) consumables and spare parts like garnet, nozzles, mixing tubes, and high-pressure seals.

Your Benefits:

Fast Access to Critical Parts: Key components can be delivered within 24-48 hours, preventing long production halts while waiting for parts.

Guaranteed Cutting Quality: Using genuine OEM parts ensures optimal cutting performance and precision while extending the life of associated components, leading to a lower total cost of ownership.

Simplified Procurement: A one-stop shop for quality-assured parts means you don't waste time and resources sourcing and testing inferior alternatives.

What we provide: Scheduled Preventive Maintenance (PM) contracts and, when necessary, rapid dispatch of certified field engineers for on-site service.

Your Benefits:

Extended Equipment Lifespan: Regular maintenance identifies and resolves potential issues before they become major failures, significantly extending the machine's life.

Predictable Downtime: Schedule maintenance during planned production breaks instead of suffering unexpected, costly breakdowns during peak times.

Efficient & Effective Repairs: When a site visit is necessary, engineers arrive informed by remote diagnostics and equipped with the correct parts to solve the problem on the first visit.

What we provide: Regular software updates, hardware upgrade paths (e.g., to a 5-axis cutting head or a higher-pressure pump), and process optimization consulting.

Your Benefits:

Future-Proof Technology: Access the latest cutting technologies and efficiency improvements