- Home

- Customization Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

1️⃣ Monoblock Gantry Frame

Manufactured with a one-piece casting process, the monoblock frame eliminates assembly errors from bolted joints. Optimized beam and column design further increases rigidity and structural stability.

2️⃣ High Precision & Stable Performance

The monoblock bed removes errors and stiffness loss caused by multi-module connections. Its rigidity is verified by finite element analysis, ensuring outstanding dynamic behavior under high-speed, heavy-load cutting. This extends tool life and guarantees consistent part quality.

3️⃣ Quick Installation & Commissioning

Designed with on-site convenience in mind, the machine minimizes assembly and adjustment time, allowing rapid transition to stable operation.

4️⃣ Modular & Low-Maintenance Design

Core components are durable and easy to access. Routine care requires no complicated steps, while self-diagnostics and standardized wear parts reduce manual inspections, failures, and maintenance costs.

5️⃣ Smart Fault Alarm

A built-in alarm light provides instant visual alerts when abnormalities occur, helping operators prevent damage and lower repair expenses.

6️⃣ Dual Safety Protection

Soft-limit and hard-limit safeguards prevent mishandling from damaging the drive system, ensuring safe and reliable operation.

7️⃣ Optimized Cabling & Service Access

Integrated cable routing simplifies wiring and installation. Relocated service ports with quick-release covers allow direct maintenance without dismantling panels—saving time during setup and servicing.

Technical Parameters

| Platform structure | Model | X-axis travel | Y-axis travel | Z-axis travel | Water tank height | Water tank load | Maximum idling speed | Cutting accuracy | Positioning accuracy | Repeat positioning accuracy | |

| Gantry | Monoblock | HEAD-2015MA | 2000mm | 1500mm | 150mm | 900mm | 500KG/㎡ | 9m/min | ±0.1mm | ±0.05mm/500mm | ±0.03mm/500mm |

| HEAD-2515MA | 2500mm | 1500mm | 150mm | 900mm | 500KG/㎡ | 9m/min | ±0.1mm | ±0.05mm/500mm | ±0.03mm/500mm | ||

| Separate | HEAD-2030SA | 2000mm | 3000mm | 150mm | 750mm | 500KG/㎡ | 9m/min | ±0.1mm | ±0.05mm/500mm | ±0.03mm/500mm | |

| HEAD-2060SA | 2000mm | 6000mm | 150mm | 750mm | 500KG/㎡ | 9m/min | ±0.1mm | ±0.05mm/500mm | ±0.03mm/500mm | ||

| HEAD-3020SA | 3000mm | 2000mm | 150mm | 750mm | 500KG/㎡ | 9m/min | ±0.1mm | ±0.05mm/500mm | ±0.03mm/500mm | ||

| HEAD-3060SA | 3000mm | 6000mm | 150mm | 750mm | 500KG/㎡ | 9m/min | ±0.1mm | ±0.05mm/500mm | ±0.03mm/500mm | ||

| HEAD-4020SA | 4000mm | 2000mm | 150mm | 750mm | 500KG/㎡ | 9m/min | ±0.1mm | ±0.05mm/500mm | ±0.03mm/500mm |

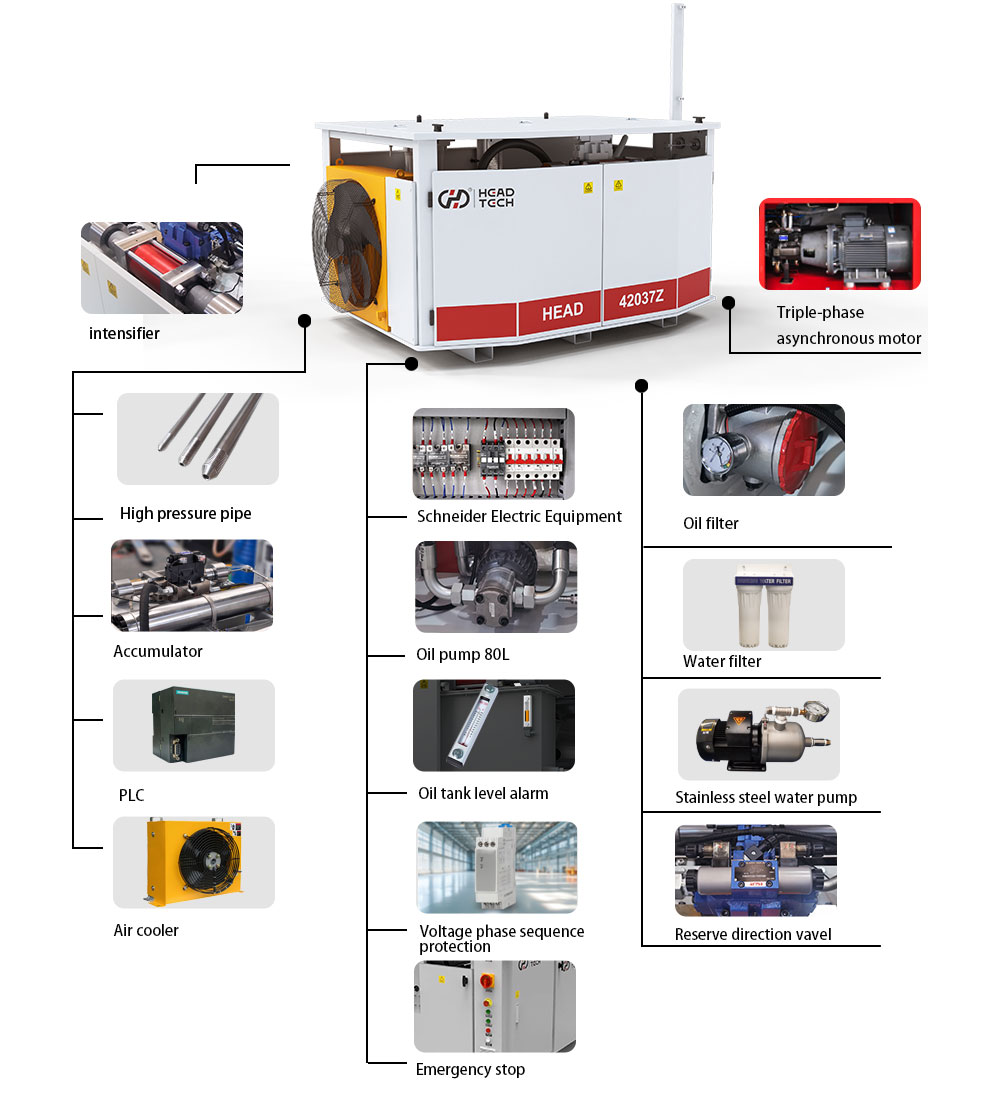

High Pressure Pump

| Rated pressure | 420Mpa(60000psi) |

| Working pressure | 50-380MPa(7200-55000psi) |

| Main motor power | 37KW(50hp) |

| Air cooler power | 0.78KW |

| Dimensions | 1900*1350*1100 |

| Weight | 1.3T |

| Maximum displacement | 3.7L/min |

| Pressure ratio | 1:20 |

| Maximum oil pump flow | 119L/min |

| High-pressure water pipe specifications | Φ3/8" |

Liquid-to-liquid boosting technology: stable and efficient pressure increase, imported parts guarantee long-term stability, worry-free operation!

Military-grade material: made of 316L seamless steel pipe, anti-yield, anti-stretching, corrosion-resistant, durability increased by 50%!

Extremely long maintenance-free: innovative "TDM" accumulator, life span exceeds 5000 hours, save worry, labor and money!

Large-capacity buffer: 1.2-liter accumulator, reduce pressure loss, increase efficiency by 20%!

Beide brand motor: cast iron body, 10% energy saving, low noise and low vibration, rock-solid performance!

80 pump super large flow: 119L/min super power, reduce pipeline resistance, efficiency soared by 30%!

ISO international standard oil pipe: resistant to pressure and fluctuation, leading system stability in the industry!

Intelligent high and low pressure switching: adapt to different materials, finer cutting, 50% reduction in roughness! (Exclusive for A25+ version)

Double insurance for pressure relief: high and low pressure water pressure relief valve, no dead angle for safety protection! (A25+ version optional)

7 kinds of intelligent protection:fault alarm, oil temperature monitoring, low pressure shutdown, motor protection, liquid level warning, filter element blockage warning, phase sequence protection, all-round protection of equipment!

Automatic shutdown mechanism: abnormal situation response in seconds, equipment damage risk is zero!

Our Service

What we provide: Professional machine installation and commissioning by certified engineers, followed by systematic training for your operators, programmers, and maintenance staff.

Your Benefits:

Peak Performance from Day One: Ensures the equipment operates under ideal conditions from the start, avoiding accuracy issues or potential failures caused by improper setup.

Empowered Team: Your operators learn to use the machine safely and efficiently, reducing material waste and preventing damage from user error, thereby maximizing productivity.

In-House First Response: Your team will be equipped to handle routine maintenance and basic troubleshooting, reducing reliance on service calls and saving time and money.

What we provide: 24/7 or extended business-hour support via hotline, online chat, or video, equipped with powerful remote diagnostic capabilities.

Your Benefits:

Instant Problem Solving: Simple issues are resolved immediately through expert guidance, eliminating waiting times.

Precise Remote Diagnostics: Our technical team can remotely access your machine's system to quickly pinpoint the root cause of a problem, whether it's software, parameters, or hardware. Over 80% of issues can be solved remotely, drastically reducing downtime.

Reduced Service Costs: Avoids unnecessary on-site visits, directly saving you travel and labor expenses.

What we provide: Local or regional parts centers stocked with high-quality, original (OEM) consumables and spare parts like garnet, nozzles, mixing tubes, and high-pressure seals.

Your Benefits:

Fast Access to Critical Parts: Key components can be delivered within 24-48 hours, preventing long production halts while waiting for parts.

Guaranteed Cutting Quality: Using genuine OEM parts ensures optimal cutting performance and precision while extending the life of associated components, leading to a lower total cost of ownership.

Simplified Procurement: A one-stop shop for quality-assured parts means you don't waste time and resources sourcing and testing inferior alternatives.

What we provide: Scheduled Preventive Maintenance (PM) contracts and, when necessary, rapid dispatch of certified field engineers for on-site service.

Your Benefits:

Extended Equipment Lifespan: Regular maintenance identifies and resolves potential issues before they become major failures, significantly extending the machine's life.

Predictable Downtime: Schedule maintenance during planned production breaks instead of suffering unexpected, costly breakdowns during peak times.

Efficient & Effective Repairs: When a site visit is necessary, engineers arrive informed by remote diagnostics and equipped with the correct parts to solve the problem on the first visit.

What we provide: Regular software updates, hardware upgrade paths (e.g., to a 5-axis cutting head or a higher-pressure pump), and process optimization consulting.

Your Benefits:

Future-Proof Technology: Access the latest cutting technologies and efficiency improvements