- Home

- Customization Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

HEAD3020BA

HEAD

| Availability: | |

|---|---|

Product Description

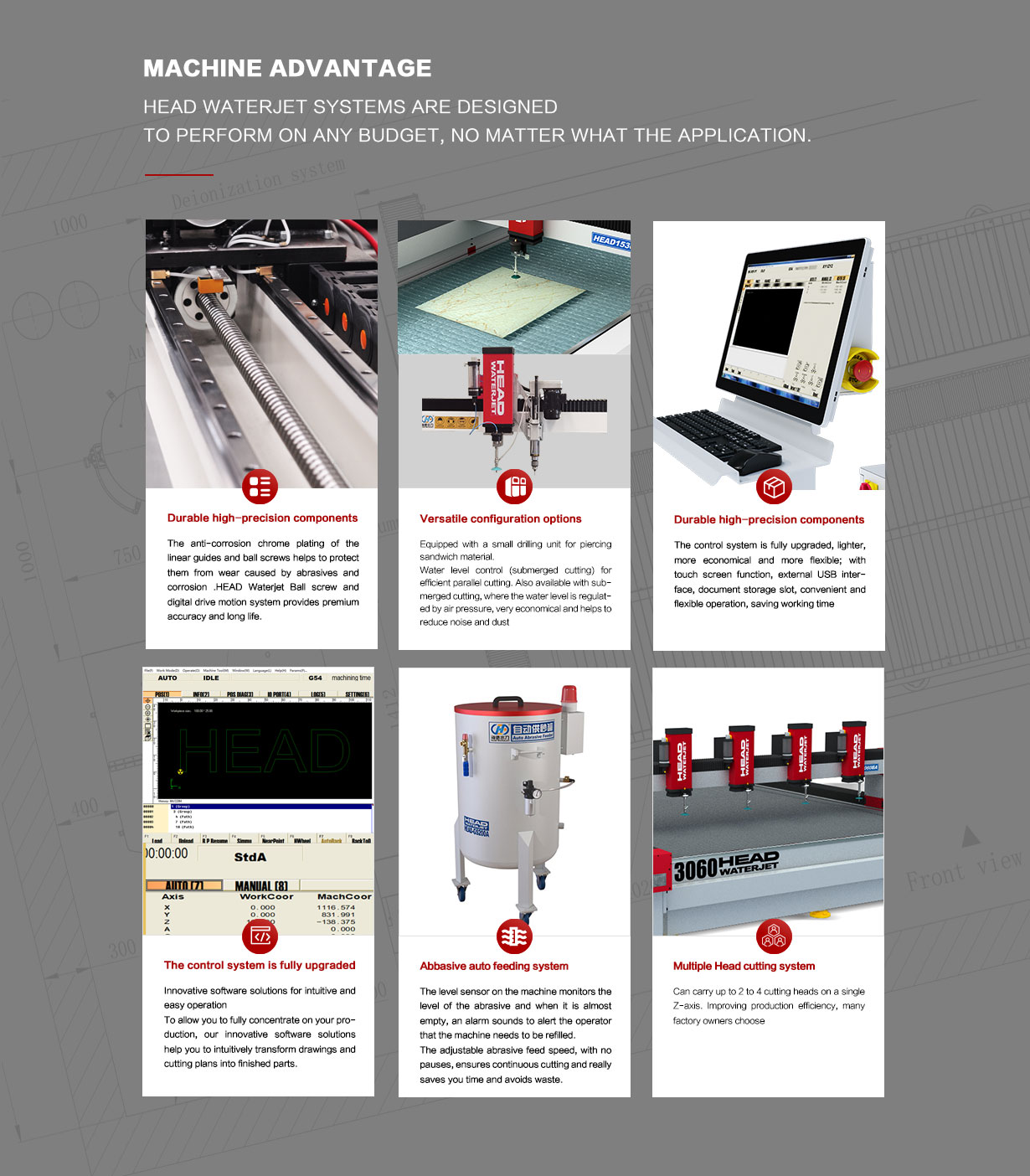

Gantry Type Water jet Cutting Machine can likewise be utilized for puncturing a material or penetrating gaps. Furthermore, the best part is, it is thought to be more productive than other warmth based cutting strategies, for example, lasers and plasma cutting. Waterjets dispense with airborne clean particles, smoke, exhaust, and contaminants from cutting materials.

• 50 HP High 420 MPa pressure for smooth finish cutting at high speed.

• Main heart of Supercharger, "Intensifier" is "Made in USA".

• User friendly & minimum maintenance cutting head design with USA make "Water Switch Seal Kit" & other parts.

• All parts of machine are processed on Highly accurate YASKAWA servo motor (made in Japan). Which gives you trouble free operation & long life of parts.

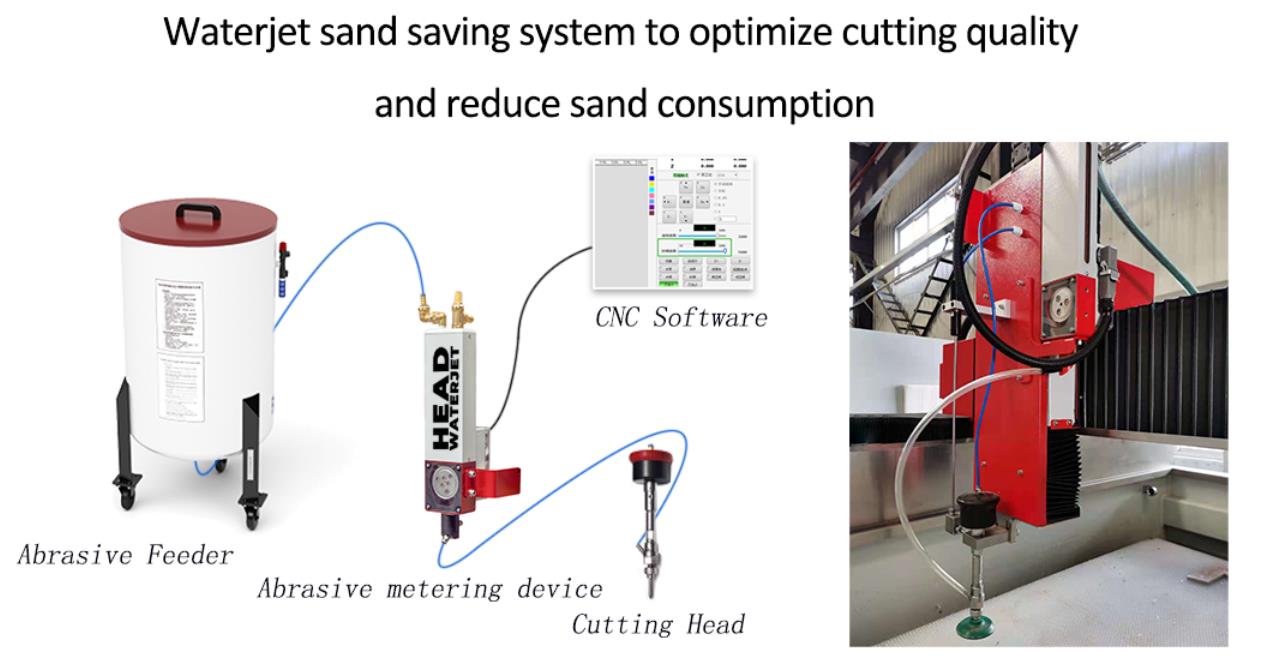

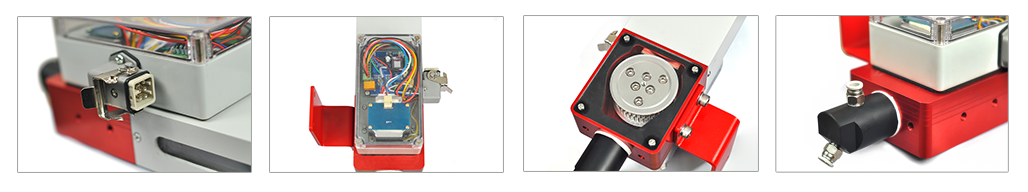

In order to better optimize the consumption of waterjet sand (abrasive) in the water cutting process, we have optimized and upgraded on the basis of the original standard sand control system, and developed a new generation of electronic sand control system. The sand flow rate is controlled by the software to ensure the consistency of the cutting surface. It is especially suitable for high-precision processing. It can better record the sand supply parameters when cutting specific materials, optimize the water jet sand consumption, and reduce the water jet usage cost.

FAQ

Q: What about the leading time?

A: In general, the leading time is about 25 to 35 days. But please confirm the exact delivery time with us as different products and different quantity will have different leading time.

Q: What’s the warranty time?

A: One year.

Q: If we need technical support, can you offer us?

A: Yes, we have an experienced team to offer technical support. Well-trained salespersons and engineers are always ready to respond to your technical doubts.

Q: How fast is the processing speed?

A: Speed depends on customers’ materials and cutting requirement, and operator can adjust speed parameters accordingly.

Hot Tags: cnc water jet cutter, China, manufacturers, suppliers, factory, price, for sale,